Automatic slab line polisher for granite

Product Features:

The polishing machine can polish all kinds of stone, including granite, marble, limestone,and so on.The maximum polishing slab size can be up to 2400*2000mm.

One worker can operate 2-3 sets polishing machines, automatic polishing makes stone processing more simple and efficient.

Also our polishing tools can improve the polishing efficiency and glossy.

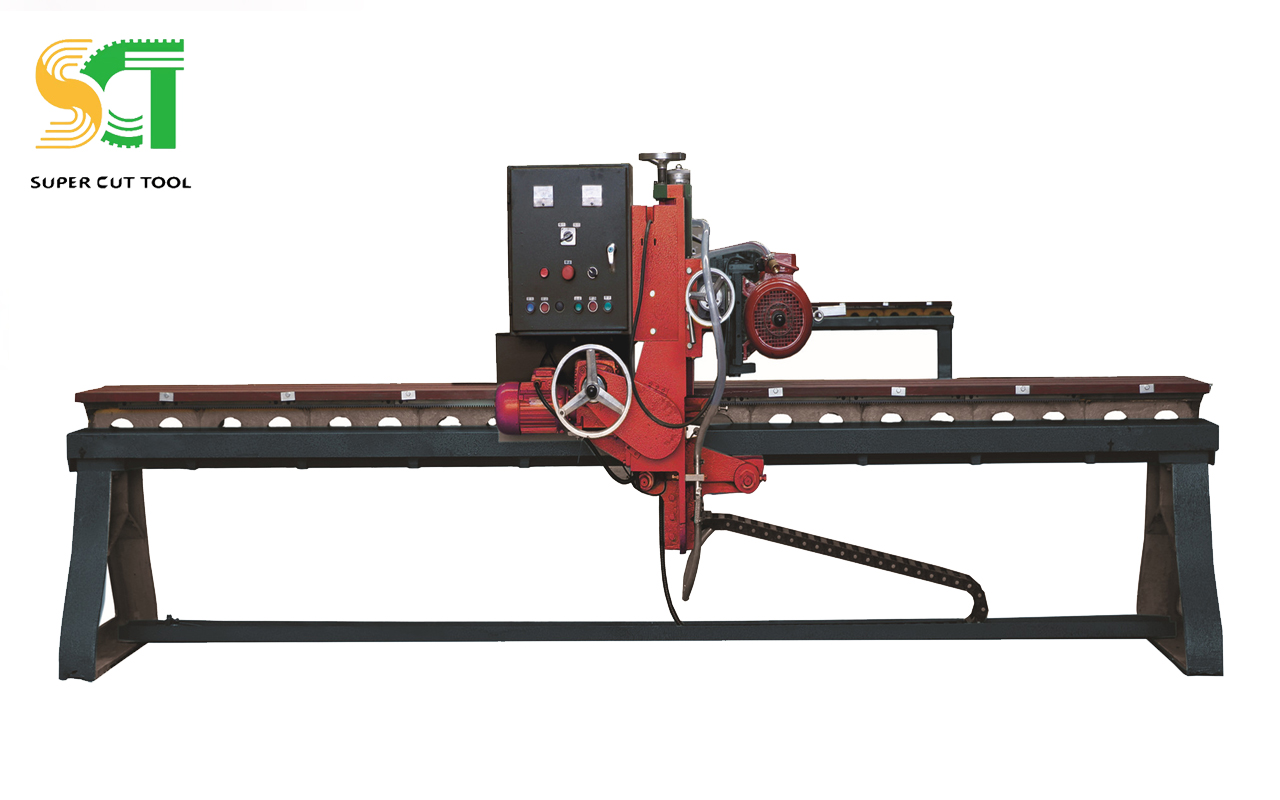

Polish&Drill

Polish&Drill

+

Automatic Slab line polisher for granite&marble

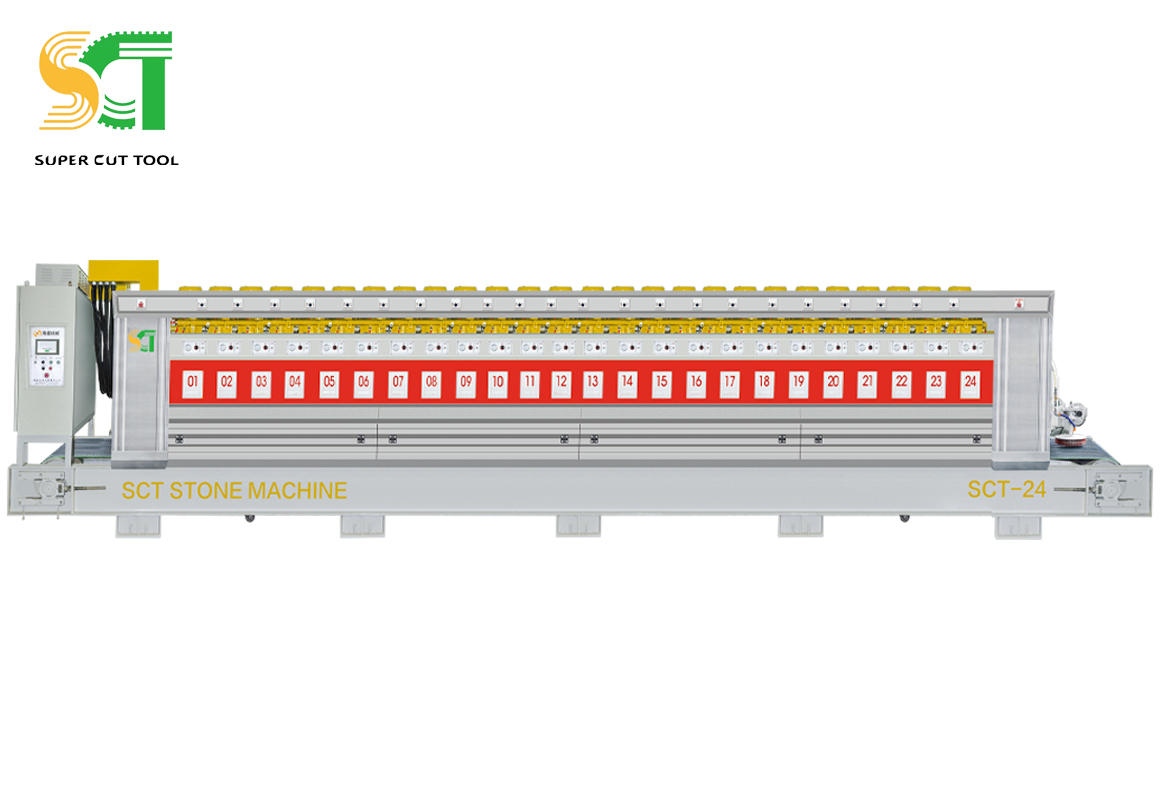

Mode: SCT-8/12/16/20/24(disc type):

Usage: The machine is made by standard castings and steel, branded electrical equipment made in German, Japan and Taiwan, as well as branded bearing, motor and gear reducer.The control system of this machine adopts PLC terminal control with LCD touch screen terminal as HMI for parameter setting and fault prompts during operation, etc. It is applicable to continuous grounding and polishing granite tile. Operating speeds of plate conveying and crossbeam of polishing disc are controlled by frequency converter; working pressure and the polishing width of tile-plate are adjustable within the setting values. This machine can also automatically identify the shape of tile-plate, so that each polishing disc (polishing head) could automatically lift and lower according to the identified shape of tile-plate, and conduct tracking records for tile-plate polishing at the same time. The overall machine is produced according the standard requirements with performance up to the leading domestic level.

Product Specification:

| Model | Unit | SCT-8 | SCT-12 | SCT-16 | SCT-20 | SCT-24 |

| The number of polishing heads | piece | 8 | 12 | 16 | 20 | 24 |

| Thickness of the effective work | mm | 15-50 | 15-50 | 15-50 | 15-50 | 15-50 |

| Effective working width | mm | 300-1300 | 300-1300 | 300-1300 | 300-1300 | 300-1300 |

| Belt feed rate | m/min | 0-2.5 | 0-3 | 0-3.5 | 0-4 | 0-5 |

| Grinding motor power | kw | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Total power | kw | 65 | 95 | 125 | 155 | 190 |

| Water consumption | m3/h | 8 | 12 | 16 | 20 | 25 |

| Dimensions | m | 4.2x2.2x2.5 | 6x2.2x2.5 | 7.8x2.2x2.5 | 9.3x2.2x2.5 | 10.8x2.9x2.5 |

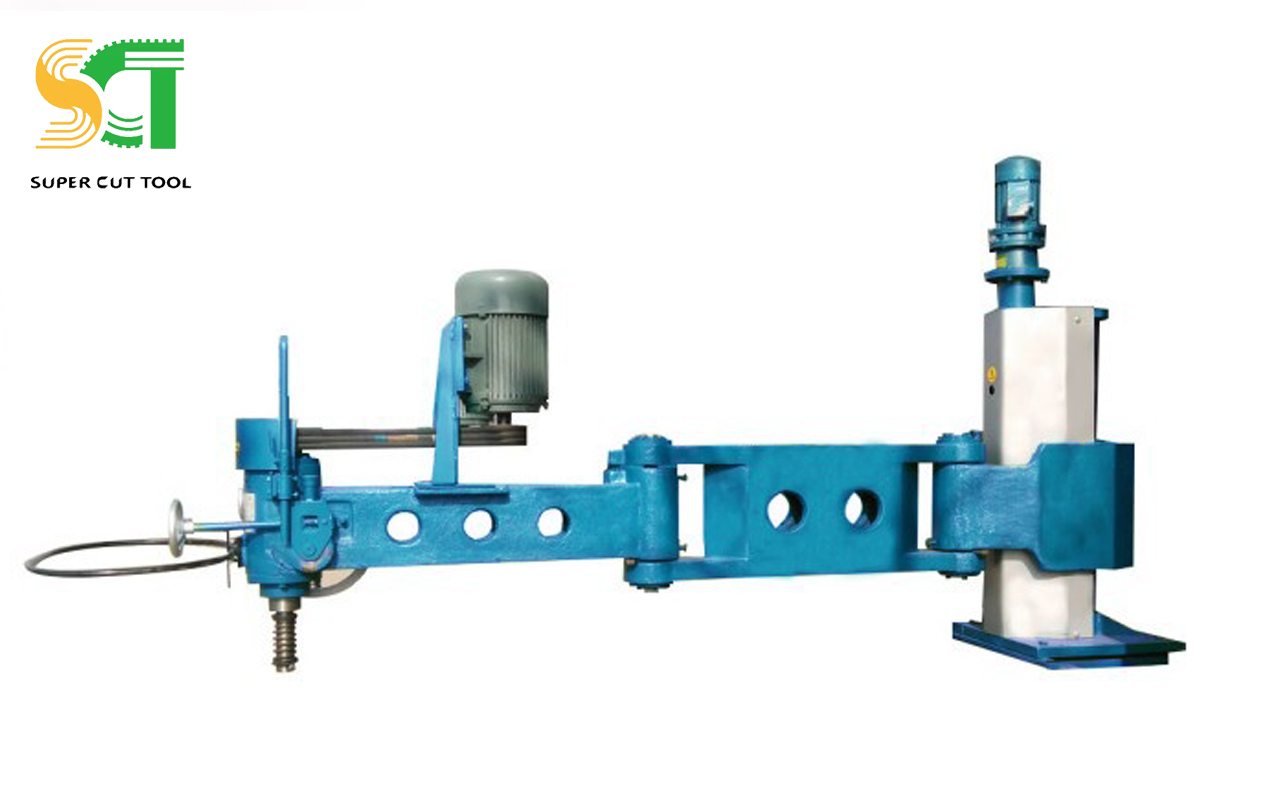

Mode: SCTM-8/12/16/20/24(fickert type):

The 2000mm width big slab polishing machine uses diamond fickert/brick,resin fickert/brick, frankfurt abrasive for processing of granite, marble, limestone and so on. The big slab polishing line give better polishing on stone slabs with high glossy and polishing efficiency.

Machines

Machines