What is a diamond tool

Definition of diamond tools: Diamond tools refer to a series of tools that use artificial diamond as a cutting material and have a certain shape made with the aid of a binder or other auxiliary materials for processing non-metallic hard and brittle materials such as stone, ceramics, glass, and concrete.

1 Diamond

Diamond is commonly known as "Diamond Diamond". It is also a diamond we often say. It is a mineral composed of pure carbon. Diamond is the hardest substance in nature, so it has many important industrial uses, such as fine abrasive materials, High-hard cutting tools, various drills, wire drawing dies. Diamond is also used as a part of many precision instruments.

1.1 Composition of diamond

Diamonds have been recorded in the literature of the first century AD, however, for more than 1600 years, people have never known what the composition of diamond is.

Until the 1970s and 1990s of the 18th century, experiments by French chemist Lavoisier (1743--1794) and others to burn diamond in oxygen revealed that carbon dioxide gas was obtained. It was proved that the material that makes up diamond is carbon.

1.2 The difference between diamond and graphite

Graphite and diamond are both carbon simple substances, but diamond and graphite are not the same substance. They are allotropics composed of the same elements. The difference is the physical structure characteristics. The chemical formula of both is c, and graphite atoms form a regular six. The rectangular shape is a flat structure, which is flaky. The diamond atoms are three-dimensional regular tetrahedron structure, which is a pyramid structure. It is this dense structure that makes diamond have the maximum hardness. In other words, diamond is a carbon atom A mineral formed by extrusion.

1.3 Diamond hardness

The hardness of diamond is generally expressed by Mohs hardness, with a hardness value of 10.Micro hardness of 10,000 kg / mm2, micro hardness is 1000 times higher than quartz and 150 times higher than corundum.

According to the Mohs hardness scale, it is divided into 10 levels, and the diamond (diamond) is the highest level 10; such as a knife, its hardness is about 5.5, copper coins are about 3.5 to 4, nails are about 2 to 3, glass hardness For 6.

1.4 Industrial Diamond

Diamonds are divided into natural diamonds and synthetic diamonds by the way they are generated.Generally, synthetic diamonds are used in the manufacture of diamond tools. They are also called industrial diamonds.

Its density is 3.52g / cm3, and its mass unit is generally expressed in "carats", 1 carat = 0.2 grams.

The particle size (particle size) of synthetic diamond is generally expressed by "mesh". Common particle sizes of artificial diamond are 25/30, 30/40, 40/45, 45/50, 50/60, 60/70 ...

2 Powder

The raw materials of diamond tools, in addition to diamond, are mainly powders. These powders can be metals, non-metals, alloys, and compounds. The powders used in diamond tools have not only certain requirements on chemical composition, but also powders. There are also different requirements for particle size, shape, loose specific gravity, compactability, sinterability, etc., which depend on factors such as the use, variety, and production process of the diamond tool.

Common metal powders and characteristics

(a) Copper powder: It is prepared by electrolytic method, and the particle shape is dendritic, rose red, darkened after oxidation, and becomes black powder when severe.

As a binder material, the main advantages of copper powder are: good formability of electrolytic copper powder, widely used for sintering after cold pressing; pure copper has good compatibility with carbides and framework materials, such as W, WC; copper can be Made with Sn, Zn, Mn, Ni, Ti and other alloys with excellent performance, the price is far lower than cobalt powder.

(b) Iron powder: There are reduced iron powder, electrolytic iron powder and carbonyl iron powder. As the name implies, reduced iron powder is prepared by reduction method, electrolytic iron powder is prepared by electrolytic method, and carbonyl iron powder is prepared by thermally dissociating carbonyl compounds. As a binder material The advantages of iron powder are: low price, good wettability with diamond; good compatibility with framework material (WC); mild etching of iron to diamond when sintering at a certain temperature does not lose the strength of diamond Instead, it will increase the diamond's holding power in the carcass. The etching effect is essentially the process in which the carbon atoms in the diamond dissolve into the iron and diffuse into it, and the structure and strength of the diamond have not changed.

(c) Cobalt powder: Irregular sponge-like, prepared by reduction method. As a binder, it has the best comprehensive performance. It is an excellent binder material. It is widely used in developed countries. Its main advantages are: excellent Formability and sinterability; can improve the bending strength of the carcass; large bonding with diamond, good wettability; good toughness and self-sharpness of the carcass. Due to the high price, domestic There are many researches on cobalt.Selecting suitable powders and reasonable sintering processes can obtain similar properties of cobalt-based binders.

The disadvantages of cobalt are: the price is expensive; the loose packing density is too small, which is likely to cause difficulty in feeding. In addition, the design width and height of the pressing abrasive tool are increased, and the height of the hand-loading hot-pressing mold is increased, which increases the cost of the mold.

(d) Nickel powder: Irregular dendritic, made by electrolytic method. Advantages: suitable for making tools that work under heavy loads, with excellent strength and toughness; can reduce sintering losses of iron-copper-based matrix (infinite mutual dissolution of copper and nickel); The combination of nickel with iron and cobalt can achieve satisfactory overall properties, such as small deformation and moderate abrasion resistance. It can approach or reach the performance of cobalt-based tire casings.

(e) Tin powder: The particles are in the form of drops, off-white powder, easy to oxidize, yellow after oxidation, and prepared by atomization. The role of tin powder in the binder is to improve the sinterability of the carcass (lower the melting point); It is easy to form intermetallic compounds, which can improve the wear performance and deformability. It is suitable to be added to the press-molded carcass, and the capillary phenomenon after sintering and melting shrinks the carcass, thereby increasing the compactness of the carcass; reducing the surface tension of the liquid alloy, improving The wettability of the alloy to diamond. Its disadvantage is that too much amount is added, which is easy to cause loss.

(f) Tungsten powder: cyan black, micron-sized powder, prepared by reduction method, tungsten has good compatibility with copper, iron, cobalt, and nickel; WC is formed on the diamond surface during sintering, but the diamond surface does not graphitize ; Increase the wear resistance of the carcass and reduce deformation; as a skeleton material, the wear resistance is not as good as WC, but it can increase the toughness of the carcass. The disadvantage is that the porosity of the sintered billet is larger, and the temperature and pressure

(g) Tungsten carbide: black, no mechanical inclusions, porous sponge, made by reduction method. The sulfur content of impurities must be tested. Sulfur easily causes the sintered section to become black (sulfide formed during sintering), which greatly reduces the strength of the cutter head. And tungsten carbide are mainly added to the carcass as a skeleton material to improve the wear resistance of the carcass.If the content is too high, the brittleness of the carcass will increase.

3 Diamond tools

Diamond tools are a special composite material made by mixing diamond particles with metal, resin and other binders according to a certain process. Due to the development of the building material industry, the use of diamond tools is becoming more and more widespread, which also makes the production of tools There are high requirements in terms of economy and performance, and the key to improving the performance of diamond tools is the wear resistance of the product, while maintaining sharpness.

3.1 Structure of diamond tools:

Diamond + metal powder = cutter head (main technology)

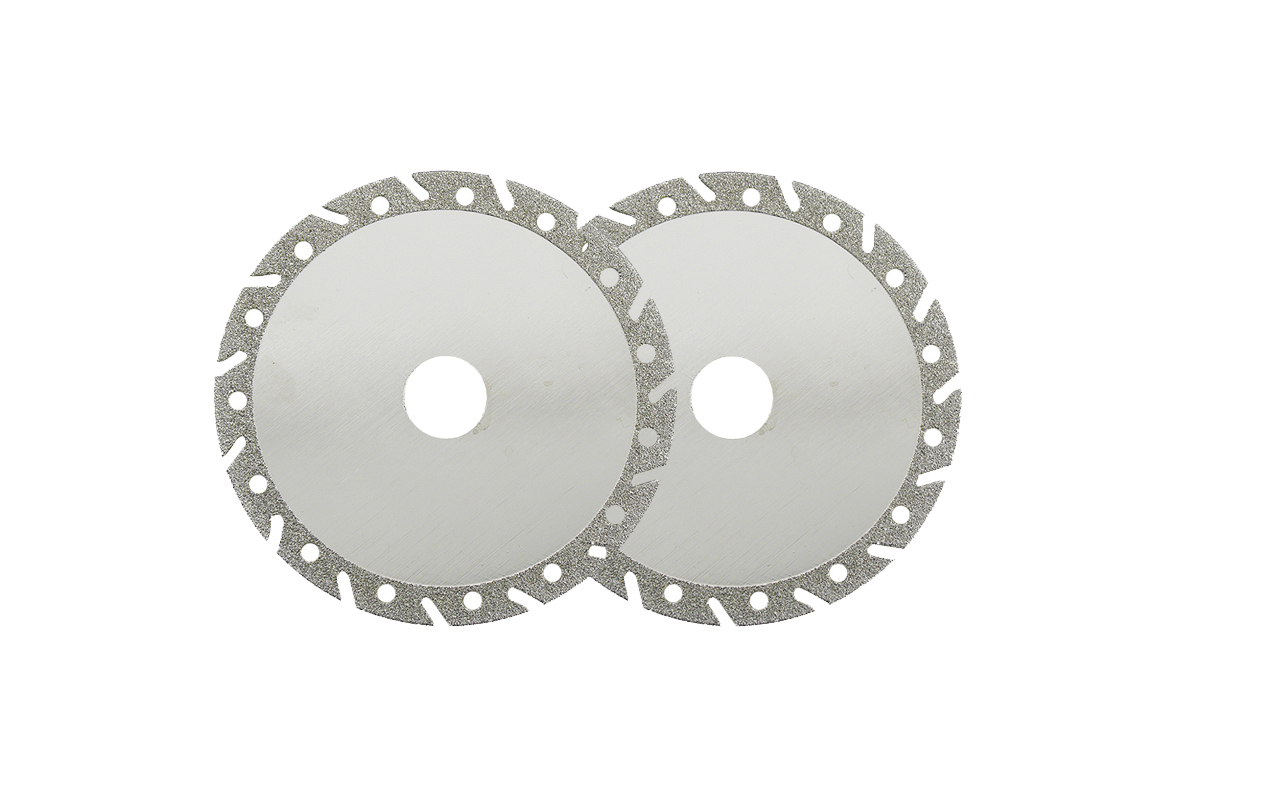

Tool head + substrate (rigid body) = diamond saw blade (drill bit, grinding disc)

3.2 Classification of diamond tools

Divided by purpose: drill, saw blade, grinding, that is, "drilling, cutting, grinding" tools.

Divided by production process: sintering, welding, electroplating products, etc.

Divided by bonding agent: metal bonding agent, resin bonding agent, ceramic bonding agent, etc.

3.3 Diamond tool concentration concept

It is defined that the concentration of diamond in the matrix is 25% and the concentration is 100%.

Concentration is one of the important characteristics of diamond tools, which has a great impact on the efficiency, life and processing effect of the tool. Generally, if the diamond concentration is high, the number of diamond particles per unit area of the working layer is large, and the force of each abrasive particle It is small, the depth of the cut into the workpiece is small, the diamond is not easy to break and fall off, but it is easy to be flattened and polished, and the macro performance is low efficiency and long life; the diamond concentration is low, each abrasive grain has a larger cutting pressure, and the cutting depth Easy to break and fall off, the tool shows high efficiency and low life.

Generally, the diamond concentration of sawing tools is mostly selected from 10% to 45%; the drilling tools and sintered metal bond diamond abrasive tools are selected from 50% to 125%; the resin diamond abrasive tools are selected from 50% to 100%; For ceramic diamond grinding tools, select 75% ~ 150% concentration; 200% concentration for electroplated diamond tools.

3.4 Raw materials for diamond tools

Substrate: The metal bond diamond tool substrate is mainly steel substrate, and the commonly used materials are 45 # steel, 65Mn, 28CrMo, 16Mn, etc.

Diamond Abrasive: It has been introduced in "Introduction to Diamond" and will not be repeated here.

Metal powder: sintered metal binder products commonly used elements are: Fe Ni Cu Mn Sn Zn AI Co Cr W Ti Ce La

3.5 Types of metal-based binders commonly used in diamond products

Copper-based binder: Copper or bronze is the main binder element, and one or more of Ni, Mn, Co, and Fe are added.

Cobalt-based binder: Cobalt has an irreplaceable position in the manufacture of diamond tools, especially when the cutter requires heavy-duty high-efficiency cutting due to its good wettability to diamond. However, its excessive price is forcing people to use iron, Nickel gradually replaced it.

Iron agent binding agent: Iron has a medium elastic modulus, and it also has good wettability to diamond.In addition, the low price is the development direction of the binding agent.

W-based or wc-based binders: Not many domestic applications, but are widely used in professional cutting asphalt roads and fresh concrete pavements in developed countries in Europe and the United States.

4 Diamond tool manufacturing process

(Metal powder + diamond + liquid paraffin), mixing, mold assembly, feeding and pressing, sintering, welding, stress adjustment, painting and cutting, inspection, packaging, storage

Mix

The main function is to fully mix the prepared powder to ensure the normal pressing of the subsequent sequence. At present, the swinging three-dimensional mixer commonly used in the diamond tool industry. This mixing equipment has three functions: rotary motion, translational swing and upside down. This kind of movement method, the powder trajectory is three-dimensional and three-dimensional, which can make the powder mix uniformly in a short time, and can refine the particles.

Granulation

(1) The fluidity of the powder is improved and improved.

(2) Reduce the segregation and aggregation of powder and diamond, make the diamond distribution more uniform, and improve the performance of the product.

(3) The loss of the cold-pressing mold is reduced.Due to the good fluidity of the powder, the diamonds are all wrapped by the powder and the distribution is more uniform.Therefore, the loss of the cold-pressing mold is reduced, and the mold life is increased by more than 50%.

(4) Improved production efficiency and created conditions for the realization of cold-press automated production.

Cold pressing

The main function is to realize the pressing molding of the product (tool head) blank through the cooperation of the mold, which is divided into manual cold pressing and automatic cold pressing.

Sintering

The sintering equipment is mainly a resistance furnace and a hot press.It mainly completes the sintering and densification of diamond tools or blades.

There are three factors that affect sintering: sintering temperature, holding time, and holding pressure.

The sintering temperature and holding time mainly depend on the composition of the carcass material, in order to make the carcass alloy well fused and fully alloyed. The sintering temperature and holding time should be appropriate, too high sintering temperature and long holding time It will cause thermal damage to the diamond, increase the hardness of the carcass, reduce the wear, and the large loss of low-melting elements, which will affect the cutting performance of the saw blade. Too low sintering temperature and too short holding time will not allow sufficient alloy Fusion causes loose tissue and reduced hardness, which reduces the life of the saw blade.

If the pressure is too low during thermal insulation, the diamond sintered body will not burn in place; if the pressure is too high, the wear of the grinding tool will be increased, and the carcass material may be lost.

Welding

Welded diamond circular saw blades connect the segment and the base together by welding. At present, there are two commonly used welding forms, one is high-frequency welding and the other is laser welding.

Post-processing

The post-processing equipment mainly includes polishing machines, blade sharpeners, stress adjustment machines, paint spraying lines and other equipment. These equipments mainly work to complete the cutting before the finished product, to meet the stress requirements of the product design, and the aesthetic requirements.

5 How diamond tools work

Under a certain pressure and a certain speed, the material to be processed is abraded by the diamond on the cutter head. In the process, the diamond also wears, breaks, and falls off. The body is also worn away, so that the diamonds behind it are exposed to continue working, and continue to complete the processing work.

6 Proper Use of Diamond Tools

The reasonable selection of diamond tools is of great significance to improve work efficiency and reduce processing costs. The following uses diamond saw blades as an example to briefly introduce some contents: (four factors)

6.1 The factors of the applicable object shall be considered: according to different processing objects, general-purpose, stone-specific, concrete-specific, and tile-specific saw blades are selected.

6.2 Consider the factors of performance matching: For cutting materials with higher hardness and poor abrasiveness, a saw blade with good sharpness and moderate life must be selected to ensure its cutting efficiency; for materials with lower hardness and high abrasiveness, select Long-life, moderate sharpness saw blades help reduce cutting costs.

6.3 Consider the influencing factors of geometric dimensions: the size and type of the saw blade should be selected according to the specifications and quality requirements of the cutting material. For example, the diameter of the circular saw blade should generally be three times larger than the work piece being cut. At the same time, it should be selected according to the processing accuracy requirements. The structure of the saw blade, that is, when the sawing surface is required to be smooth or to process thin and fragile materials, narrow groove or continuous tooth saw blades should be used.Conversely, if the sawing surface requires less or thicker materials, a wider width can be used. Grooved saw blade.

6.4 Consider the influencing factors of using the equipment: wear-resistant saw blades can be used to ensure the life of the equipment with large power, and sharp products are selected to ensure its cutting efficiency. It is good to choose wear-resistant saw blades.For newer precision cutting machines, you can choose fast sharp saw blades.

7 Diamond tool formula design overview

The formula of the diamond tool refers to the formula of the powder pressed layer, including the formula containing the diamond layer and the formula of the transition layer.

7.1 Formulation basis

The formula design is based on many factors, mainly these points: the material of the workpiece to be processed, the processing method, the processing quality requirements, the processing equipment, the performance of the selected raw materials, and the selected manufacturing process.

7.2 Experimental procedures before formula determination

The first draft of the formula is based on the basis of design.It is only a theoretical design.Whether it can meet or meet various requirements in the end requires systematic experiments to verify and finally determine.

The first step: choose the composition and ratio of the binding agent (generally, several types of ratio are designed for optimization)

Step 2: Determine the strength, hardness, and other properties of the binder sample, and choose a good binder (one or two)

The third step: using the selected binding agent, according to the envisaged formula and setting process, trial production

Step 4: Perform a "cutting drill" experiment to determine the properties of the product, so as to choose the best formula

7.3 Formulation calculation

The input of general diamond products increases the sintering material loss by 5% after calculating according to its theoretical density. The formula is as follows:

m=ρ*V

In the formula: m——theoretical feeding amount

ρ——theoretical density of formula

v——product tooth volume

The theoretical density of the formula is calculated using the following formula:

ρ=100/(g1/ρ1+g2/ρ2+…+ gn /ρn)

In the formula: g1, g2,… gn——the percentage of each component in the formula.

ρ1, ρ2,… ρn——the density of corresponding components.

Calculation example: The proportion of a certain formula (without diamond) is Fe40%, Sn5%, Ni5%, Cu50%, how many grams of the sintered 40 * 10 * 4 cutter head?

Solution: The theoretical density of the formula is

ρ=100/(40/7.8+5/7.3+5/8.9+50/8.9)=8.34g/cm3

The cutter head volume is: V = 40 * 10 * 4/1000 = 1.6 cm3

Theoretical feeding: m = ρ * V = 8.34 * 1.6 = 13.3g

Actual input: m solid = 13.3 * 1.05 = 13.95g

8 Application of New Technology in Diamond Tools

8.1 Application of Pre-alloyed Powder in Diamond Tools

The pre-alloy powder has a fairly uniform composition because each powder particle contains various metal elements that make up the alloy. Because its eutectic point is much lower than the melting point of the single element in the alloy, the sintering temperature required for the pre-alloy powder is low .

At present, the common methods for preparing pre-alloyed powder are the following:

(1) Atomization method

The pre-alloy powder high-pressure atomization method is based on the designed carcass ratio, and the metals of various components are smelted into an alloy before sintering, and then atomized and powdered to obtain the carcass powder with the required particle size. The atomization medium can be divided into water atomization and gas atomization, and gas atomization can use air, nitrogen or argon. Gas atomization has fast cooling speed, fine powder grains, high powder yield and low cost. The gas has a large viscosity and strong cooling ability.The water atomization method is particularly suitable for metals and alloys with higher melting points.

(2) Co-precipitation method

The co-precipitation method is to add a precipitating agent and a surface modifier to a solution containing two or more metal ions. By strengthening the process conditions, various metal ions are precipitated at the same time to obtain a uniform precipitate. After the precipitate is processed by heating decomposition, reduction, crushing, sieving and other processes, the method to finally obtain the required powder.

The co-precipitation method is an important method for preparing composite powders containing two or more metal elements. Because the components of the chemical co-precipitation method can achieve uniform intermolecular mixing in solution, the components of the product are uniform and stable, and other parameters ( (Such as particle size, particle shape, etc.) are also easy to control. The prepared powder has the advantages of fine particle size, narrow particle size distribution range, uniform component distribution, high purity, and good sintering activity.

(3) Mechanical alloying method

The mechanical alloying method is also commonly referred to as high-energy ball milling.It is a method of loading different metal powders or dispersion-enhanced powders into a high-energy ball mill, and performing a long-time ball milling at a certain ball-material ratio and ball size ratio under a protective atmosphere. Under the action of mechanical driving force, the powder undergoes repeated extrusion, cold welding and pulverization processes, so that different raw material powders are closely bonded at the atomic level.If the raw material contains hard particles such as metals or ceramics that cannot be miscible in the solid state, The hard particles are evenly dispersed and embedded in the softer metal particles to obtain a composite powder.

A significant feature of the mechanical alloying method is that it can synthesize materials that usually require high temperature processing to prepare at low temperatures, and can obtain materials such as amorphous alloys and supersaturated solid solutions that are difficult to obtain by conventional methods. It will bring impurities into the powder to reduce the purity of the product, and repeated extrusion will cause a large internal stress in the powder, which will affect the powder's pressing performance and sintering performance.

8.2 Orderly arrangement of diamonds

In conventional diamond saw blades, diamonds are randomly and randomly arranged in the metal matrix. Therefore, diamonds are prone to segregation and aggregation in the cutter head. In the diamond-rich region, the diamond concentration is high and the cutting force of a single diamond is high. Small, easy to be polished and abraded, at the same time easy to block and hinder the removal of cuttings, resulting in reduced sawing efficiency; in the diamond sparse area, because a single diamond bears an excessive working load and a large impact force, the diamond is easy to chip and fall off Therefore, the diamond saw blades with disorderly arrangement have the problems of low sawing efficiency, short tool life and contradictory sawing efficiency and life. In recent years, in the diamond tool industry, the design and process of orderly arrangement of diamond bits have been introduced. It can evenly arrange diamonds with optimal spacing in the production of diamond cutter heads. Test data shows that the orderly arrangement can simultaneously improve the sharpness and life of diamond saw blades, and reduce the diamond concentration and save costs.

8.3 Brazed diamond tools

Brazed diamond tools use diamond surface metallization technology to weld diamond with active brazing material or nickel-based brazing filler metal. By using strong carbides to form elements or alloys, the diamond and the tool carcass can be chemically and metallurgically bonded, which greatly improves the control of diamond In addition, the diamond can protrude 2/3, and it is not easy to fall off, and it has created favorable conditions for sharp cutting and good chip removal. In addition, it is easy to combine with the diamond orderly arrangement technology to achieve a reasonable and uniform diamond on the tool surface. The cloth makes full use of the cutting effect of diamond, which can save the amount of diamond, reduce the cost of tools, and improve the cutting efficiency.

There are two main types of brazing equipment currently used. One is a high-frequency induction welding machine; the other is a high-temperature vacuum furnace.

Application of diamond in stone processing

What is a diamond tool

Super Cut Tool brand diamond wire saw

RETURN

RETURN