YOU ARE HERE >

HOME >

INDUSTRY NEWS

Application of diamond in stone processing

Publish Date:2020-03-10

Brief:In order to improve the productivity furtherly, there are a lot of researches focusing on improving the economics of stone processing technology. In addition to improving the output of materials and reducing the cost of waste materials, and diamond manufacturers, machine tool manufacturers and tool manufacturers have conducted a lot of research to increase the production capacity of machine tools and tool matching.One of the studies indicates the level of production capacity of marble machine tools at present. The highest efficiency granite sawing machine currently used in Europe is only equivalent to about 4% of the marble processing level. Generally speaking, when the cutting depth is bigger than 25 mm, it is unlikely to be used for processing granite, because it will cause a lot of heat and overload of diamond tools.

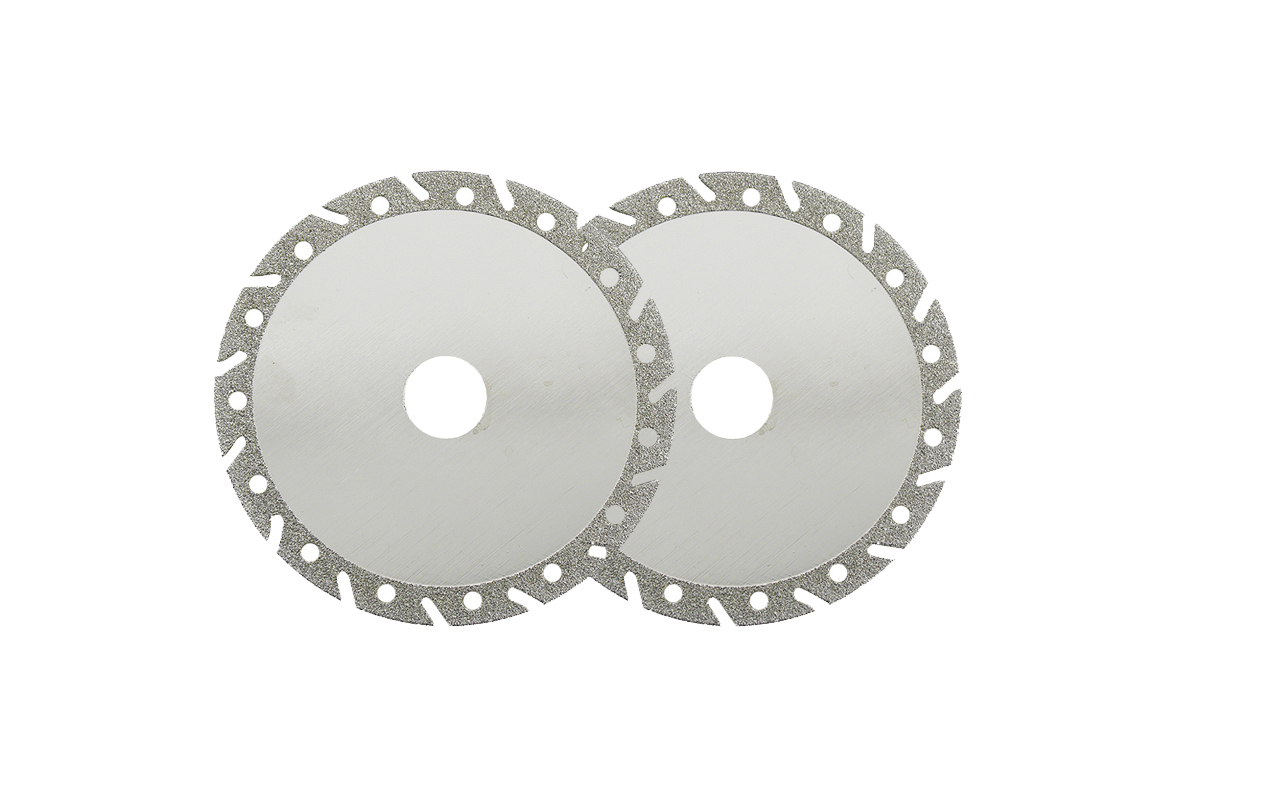

Diamond manufacturers, diamond tool manufacturers, machine tool manufacturers, sawing base manufacturers and an European Institute of international organizations, and a research institute have begun to explore a new world of stone processing technology. The focus is to find the way to solve the problem, as well as the comprehensive evaluation of technology, economy and environment, and the approach of the problem. The goal of this plan is to develop all subsystems of the machining system to meet the needs of deep-seated conditions, that is, the range of cutting depth is from 100 to 300 mm. It includes an efficient diamond circular saw blade and an improved system to provide lubrication at the interface between tool and workpiece, so as to ensure long and stable operation. Because this is a basic requirement for a highly automated process. The research work is divided into two stages:

1. Carry out lab tests in order to get some basic information (material performance, cutting force, temperature and vibration) so as to get the basic data for the machinery and tools.

2. On the support of the first stage data, the development of tools and machine tool components (saw blade caking, lubrication and trimming system) is conducted.In the first stage, one of the key points of the project design is to use the small saw blade simulation to investigate the machining force, the temperature at the interface (grinding area) between the tool and the workpiece, and the vibration characteristics. When using small saw blade, it is very important to match the system characteristics with the actual conditions in industrial application. In order to meet this requirement, many authors put forward various sawing models. Two main variables in the system are recognized, namely, cutting speed (VC) and cutting depth (AE). By using these parameters and the information about the tool geometry, a simplified model formula for circular saw blade cutting can be raised.

heq=aeVft/Vcλ

By using this formula, similar conditions and forces in normal industrial applications can be reproduced.

Measurement of cutting temperature and cutting force under deep sawing condition.

Deep sawing is carried out in a small laboratory test to measure the heat and cutting forces generated in the cutting area. This information is necessary for determining the lubrication equipment of large-scale production saw and predicting the cutting force that diamond tools may bear in the process of machining. High strength diamond is used, its particle size is 30 / 40, and the number of particles per carat is 660 ± 30. First saw the medium hardness of Italian granite, and then saw the more difficult to process Indian red granite, which is one of the most difficult materials. In the sawing test, the sawing depth is kept at 90mm, and the feeding speed is adjusted to change between the mildest cutting condition of 100cm2 / min and the worst condition of 600cm2 / min. This condition can meet the industrial production set production efficiency of 380cm2 / min to 1000cm2 / min. The temperature measurement results are obtained. As expected, the cutting temperature increases with the increase of sawing efficiency, but even at the highest speed, the cutting temperature is still lower than 200 ℃. Using dynamometer to measure the normal force and tangential force in machining, it can help the design of sawing machine and the development of the maximum size tool specification. The analysis of cutting force and the investigation of diamond wear process determine the stage in which the work should be carried out. This is the key to keep diamond wear uniform and to adjust the exposure height of diamond used to complete material cutting.

Processing requirements of granite deep saw

Based on the information obtained in the first stage, the specially designed processing equipment related to deep sawing process is determined. Considering the design of diamond saw blade, the following tool design requirements are mainly checked. The specification of the tool and the processing conditions must ensure that the chip thickness is achieved when the material removal rate matches the diamond exposure height. Under the condition of deep sawing, it is different from the case of small cutting thickness. The main concern is that if the cutting parameters are too large, the chip thickness will exceed the diamond exposure height. In this case, because the diamond particles show too much brittleness, the gap between the workpiece and the binder will be insufficient and catastrophic failure will occur. This will lead to the increase of normal force and catastrophic failure of tools. On the other hand, the project plan focuses on the stability of machine tools, lubrication power and other requirements, which should be considered when the deep saw is finally assembled.

Tags:

diamond

Application of diamond in stone processing

2020-03-10

Brief:In order to improve the productivity furtherly, there are a lot of researches focusing on impr...

What is a diamond tool

2020-04-23

Definition of diamond tools: Diamond tools refer to a series of tools that use artificial diamond as...

Super Cut Tool brand diamond wire saw

2020-10-16

At present, the largest use of diamond wire saws is in mining. Compared with previous mining methods, the benefits of wire saw products are not available in other tools. This article will focus on diamond wire saws in stone mining and stone processing. The application on the equipment, the characteristics of our country's diamond wire saw and the current development trend and direction....

Introduction and classification of diamond sawing tools

2020-09-09

Diamond sawing tools are widely used in the stone industry, from block mining, block shaping, block cutting into large slabs, cutting large slabs into tiles, and cutting stone into various special-shaped products, etc. It is a common application of diamond sawing tools in the stone industry. This article introduces the development of various diamond sawing tools in the stone processing industry by introducing common sawing tools and the development of the domestic stone industry....

RETURN

RETURN