YOU ARE HERE >

HOME >

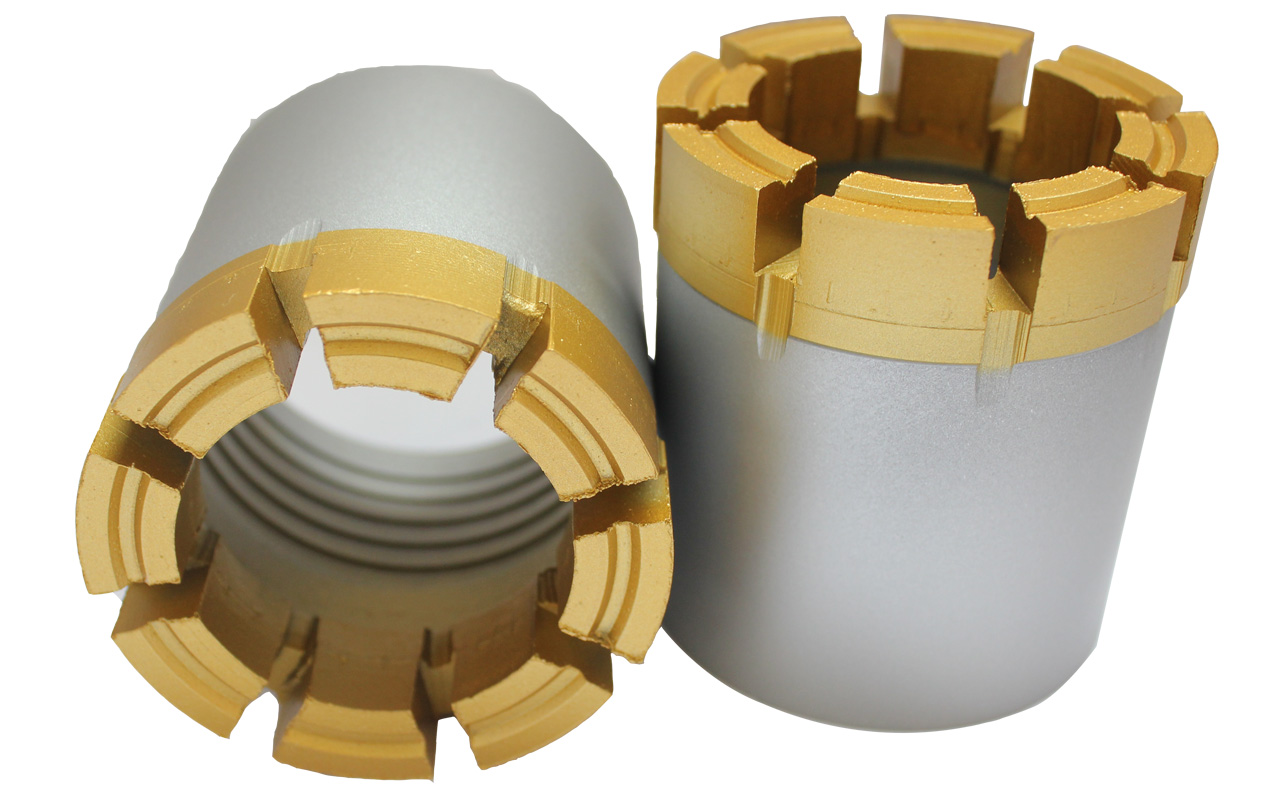

DIAMOND DRILL BIT

The structure of the diamond bit and cutting material

Publish Date:2020-11-09

The overall structure of the diamond bit, diamond drill bit is an integrated drill bit. The whole drill bit has no moving parts. It mainly includes the bit body, crown, hydraulic structure (including water eye or nozzle, flume also known as runner, chip flute), gauge, cutting edge (tooth).The crown part of the diamond drill bit is the working part of the drill bit for cutting rock. Its surface (working surface) is inlaid with diamond cutting teeth and is arranged with a hydraulic structure. Its side is the gauge part (inlaid gauge teeth), it connects to the bit body, drill bit body is made of tungsten carbide carcass or steel material.

The drill bit body is a steel material, the upper part is threaded and connected to the drill string, and the lower part is connected to the crown carcass (the steel crown is integrated with the bit body).

The hydraulic structure of diamond drill bits is divided into two categories. One type is used for natural diamond drill bits and TSP drill bits. The drilling fluid flows out from the central water hole of the drill bit and is distributed to the working surface of the drill bit through the water groove on the surface of the drill bit to cool, clean, and lubricate the cutting teeth, and finally carries cuttings from the side flume and chip flute into the annular space. The other type is used for PDC drill bits. The drilling fluid flows out from the water hole, and is distributed to various parts of the drill bit working surface to cool, clean and lubricate the cutting teeth through various diversion elements. The position and number of water holes of the PDC bit are determined by the bit structure.

The gauge part of the diamond drill bit plays the role of righting the drill bit and ensuring that the diameter of the well does not shrink during drilling. The method of inserting diamonds on the side of the bit steel body is used to achieve the purpose of gauge.

Diamond drill bit cutting tooth materials are divided into two categories: natural diamond and synthetic diamond. Diamond is a crystal of carbon. The crystal structure is a regular tetrahedron. The carbon atoms are connected by covalent bonds. The structure is very stable. Typical shapes include cubes, octahedrons and dodecahedrons.

Diamond is the hardest material, the strongest compressive strength, and the highest wear resistance among the materials currently known to mankind. Therefore, it is the most ideal material for the cutting edge of a drill.

However, diamond as a material for the cutting edge of a drill bit has a major weakness. First, its brittleness is relatively large, and it will crack when encountering an impact load. Second, its thermal stability is poor. Diamond burns into carbon dioxide and carbon monoxide (carbonization) at high temperatures. In the air, between about 455 and 860°C, the diamond will undergo graphitization and combustion; It will not be oxidized in inert or reducing gases, but at about 1430°C, diamond crystals will suddenly burst and become graphite. Therefore, in the design, manufacture and use of diamond drill bits, it is necessary to avoid high impact loads on the diamond material and ensure timely cooling of the diamond cutting teeth.

Tags:

The structure and characteristics of diamond drill bits

2020-08-17

Diamond bit is a very broad concept. It is a tool for drilling with diamond powder embedded in the bit body. Because diamond products are very rich, such as PCD, PDC, ordinary diamond powder, etc., it is formed a series of product lines of diamond drill bits. This article mainly introduces common diamond drill bits and their common structures and characteristics....

The structure of the diamond bit and cutting material

2020-11-09

The diamond drill bit is composed of five parts: drill body, crown, hydraulic structure, gauge, and cutting edge, each of which has its own function. As the main part of cutting, the cutting material of the drill bit is also a very critical part. This article introduces the structure of the diamond bit and the cutting bit, so that everyone has a preliminary understanding of the diamond bit....

Advantages and disadvantages of diamond drill bits

2020-08-17

Diamond drill bits have obvious advantages and disadvantages. The advantages are high hardness, high compressive strength and good wear resistance. But the shortcomings are also obvious, such as relatively brittle, easy to crack, and then low thermal stability, easy to become graphite with low hardness. This article helps us understand this part of knowledge....

RETURN

RETURN