YOU ARE HERE >

HOME >

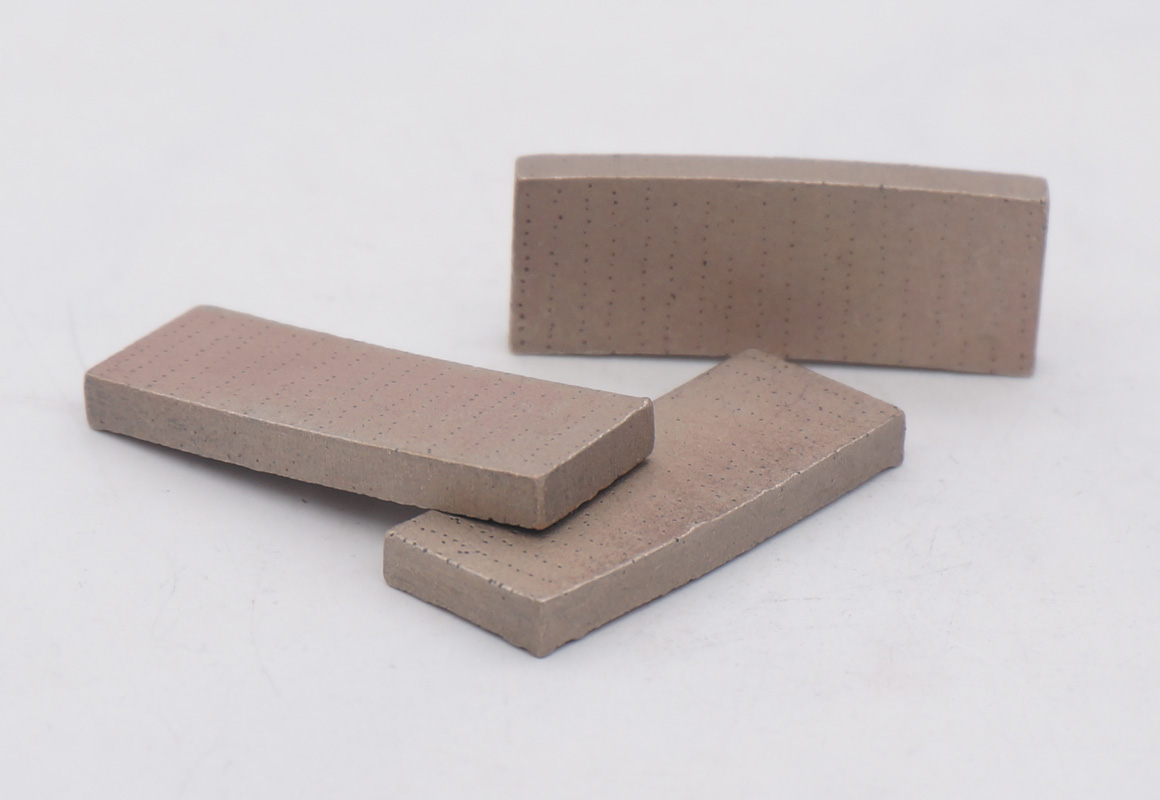

DIAMOND SEGMENT

The reason why diamond segment are designed into different shapes

Publish Date:2020-03-10

The geometric shape of diamond segment is also one of the important factors that determine the cutting performance of diamond saw blade. Different shapes of segments directly affect the sawing efficiency and the ratio of diamond abnormal failure. At present, the adopted nodal shape structure includes ordinary medium convex nodal block, layered "sandwich" medium concave nodal block, L-shaped nodal block, stepped nodal block, segmented nodal block and side slotted nodal block, as shown in the figure below respectively. The shape and structure of diamond segments are designed to improve the capacity of chip holding, chip removing, cooling and lubrication of diamond segments in the sawing arc area, reduce the friction between diamond segments, stone materials and sawdust, improve the rock breaking ability of diamond, so as to reduce energy consumption and improve the performance of saw blade. The first diamond circular saw segment adopts a uniform rectangular structure, which will start after sawing for a period of time The edges of Rui's two sides are easier to wear than the middle. In the cross-section direction, the nodal block will become convex shape, the working surface of the nodal block and the stone area will increase, and the diamond is easy to be blunt. In the actual processing, it is often necessary to use abrasive materials for cutting. In addition, due to the increase of cutting force, diamond is easy to be blunt. In practical processing, it is often necessary to use abrasive materials for cutting. In addition, due to the increase of sawing force, the saw blade matrix is prone to generate bending and vibration deformation, resulting in uneven thickness of the processed plate and repeated use of the matrix. To a great extent, the invention of layered medium concave segment solves the problems in sawing ordinary segments. The concave joint block can be realized by the following methods:1. The concentration of diamond in the outer layer is higher than that in the middle layer;

2;the outer binder is more endurable than the middle one.

3. The grade of diamond in the outer layer is higher than that in the middle layer;

4. The working length of the middle layer is shorter than that of the outer layer through structural design, such as "back" type, "H" type or other forms of middle slotting;

5. Add non working layer in multi-layer structure and adjust the width ratio of working layer and non working layer.

Because of the existence of intermittent flume around the saw blade, the length of the segment also affects the performance of the saw blade. Some scholars have discussed the design and influence of the length of the segment from the theoretical and experimental perspectives. During sawing, the load of diamond grains on the front end of the segment which is advanced into the sawing arc area is larger than that on the back end. According to different segment bearing models, appropriate segments can be designed to match the performance of the front and rear ends of the segment with the load.

In a word, at present, from the selection of diamond and binder to the design of nodal shape and parameters, it is more based on experience rather than strict theoretical basis.

Tags:

The control ratio of the metal content in the diamond segment bond

2020-08-17

The diamond segment is composed of two parts of the bond and the diamond, and the bond is actually not just one component, it is made of paraffin, nickel, tin, zinc, copper, iron, silicon carbide, tungsten and other metal powders, and non-metallic powder, in which copper, iron, silicon carbide and tungsten are the main components, while nickel, tin, and zinc are the metal binders, which make the diamond and the bond more firmly....

Selection of diamond powder for diamond segment

2020-09-24

During the diamond segment working process, the role of diamond powder crystals is very important, especially in the cutting process, a good crystal can be very good in anti-breakage ability, reduce the power consumption of the equipment, and extend the life of the cutting....

Arrayed diamond segment and the saw blade

2020-12-29

In traditional diamond segment products, the diamond powder in the segment is arranged in disorder. During the cutting process, the exposed diamond will impact the stone surface at various angles, and the exposed height of the diamond will vary. As a result, the diamond is not evenly stressed, and diamonds with high exposure are prone to fracture. In order to improve this situation and make the diamond distribution more uniform, arrayed segments have emerged. Weld the arrayed segment on the blade steel body to be an arrayed saw blade....

Commonly used bond for diamond segment

2020-09-09

There are four commonly used bonds for diamond segment. These four bonds are matched with different diamond powders according to different materials to make diamond segments for different purposes. Each bond has its advantages and disadvantages. In the process of designing the diamond segment, we must take advantage and reinforce its shortcomings. This is the charm of diamond segment production and design....

Common problems and treatment methods of diamond segment

2020-08-17

Diamond segment is a non-standard industry in modern industry. The instability of product quality is the most common problem. The following are some of the most prone problems and related solutions in producing diamond segments. Through these instructions, Let everyone better understand the details of diamond segments production process....

Formula design of diamond segment

2020-10-16

Diamond segment is a very special segmented product. Through different formulas and different processes, products with different appearances, different cutting performances and different cutting life can be produced. The most attractive part of this product is that it is not Certainty, especially the new formula, needs to consider factors such as the object to be processed, the matrix metal bond, diamond grade and particle size, pressure and sintering temperature....

RETURN

RETURN