The granulating process of diamond products and the advantages of diamond segment after granulating

The process of diamond granulation is generally as follows: in the additional mixer, the metal powder, diamond and the artificial adhesive that plays the role of bonding are first dry mixed, then added with solvent and then wet mixed. From the hopper on the upper part of the granulator, the mixture is continuously input into the internal container of the machine by the screw conveyor to make coarse particles. By mechanical rolling, coarse particles are transformed into final spherical or strip like small particles. It is then delivered to the conveyor belt and evaporated after drying. The pelletized molding material flows into the collector for standby.

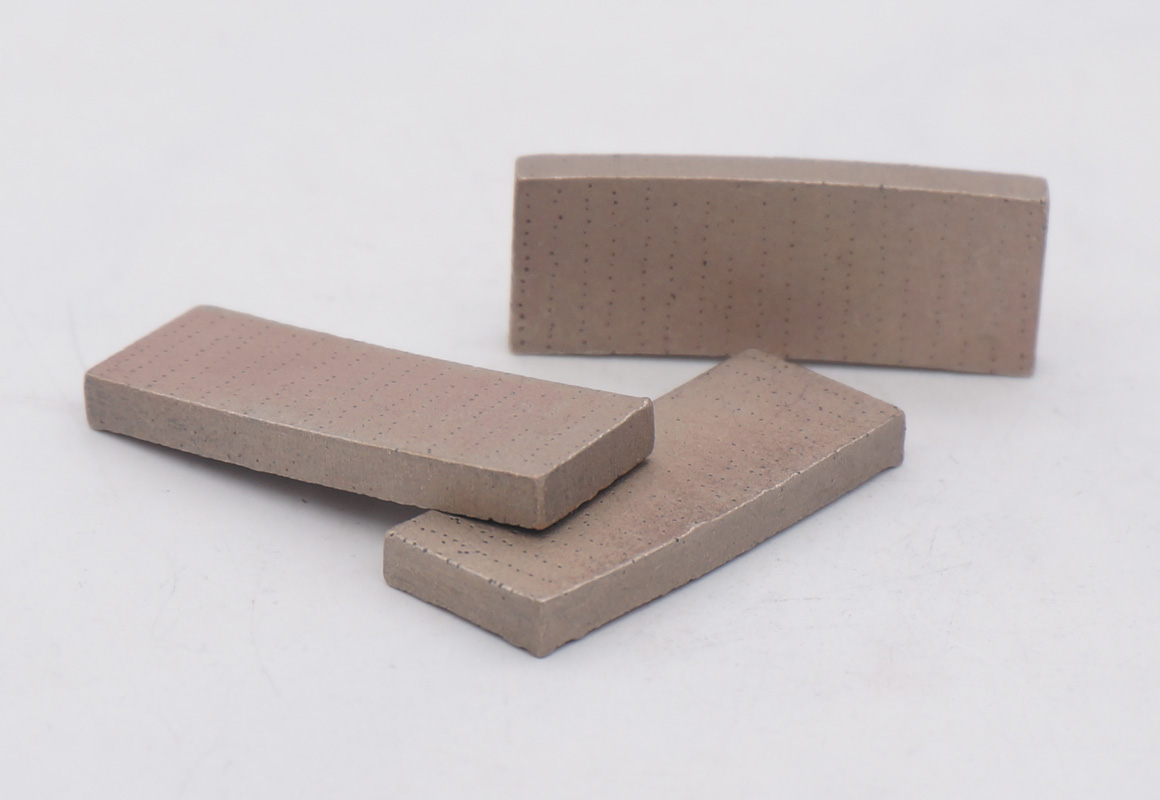

As the diamond segment is made of the formed material after granulation, the diamond and binder are evenly mixed, the diamond is evenly distributed, and the particle size is relatively uniform. The loose density and the rolling density increase, so the fixed volume (i.e. fixed volume) loading can be used instead of the quantitative loading, which greatly improves the productivity. At the same time, this can avoid the delamination of diamond and binder, and the quality is guaranteed.

The control ratio of the metal content in the diamond segment bond

Selection of diamond powder for diamond segment

Arrayed diamond segment and the saw blade

Commonly used bond for diamond segment

Common problems and treatment methods of diamond segment

RETURN

RETURN