YOU ARE HERE >

HOME >

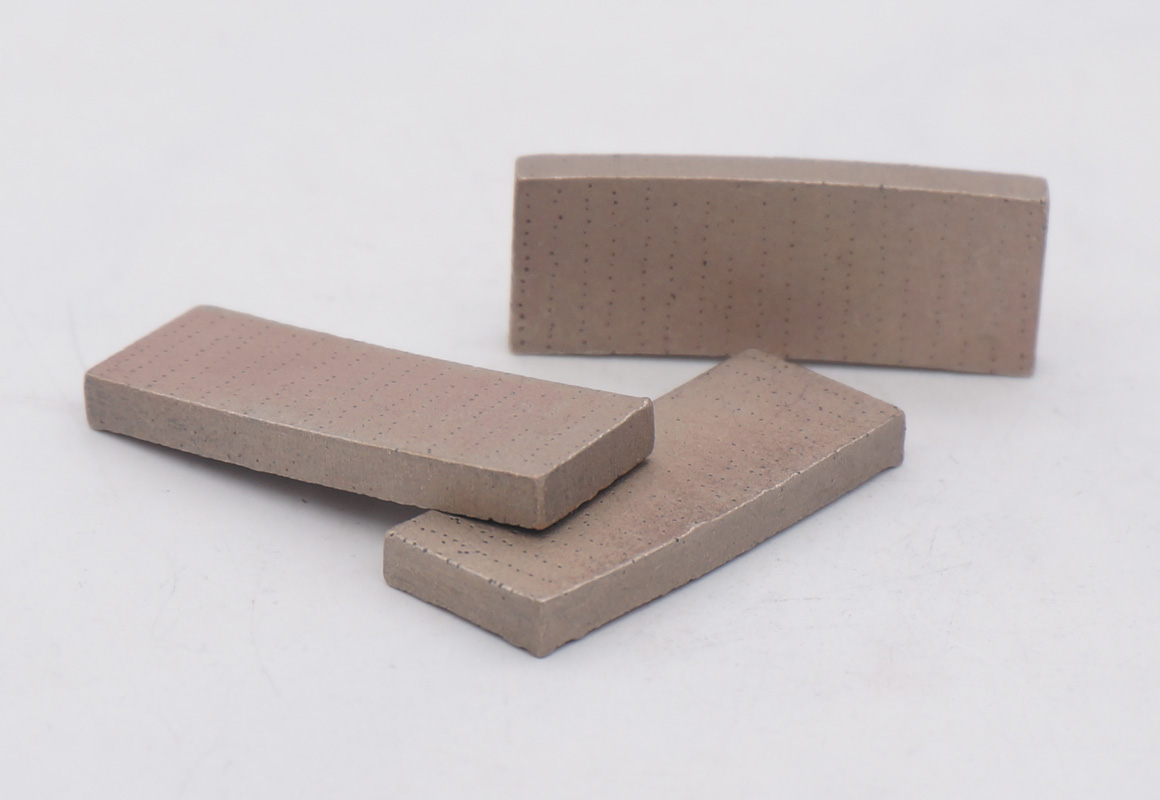

DIAMOND SEGMENT

How to choose diamond for diamond segment

Publish Date:2021-02-03

In the production process of diamond segments, diamond is an extremely important raw material. When selecting it, there are five aspects that need to be paid attention to. Let's take a look:1: Diamond grit

Diamond grit is also called diamond particle size. Choosing an appropriate grit is the key to ensuring tool performance. The exposure or protrusion height of the diamond on the cutting surface of the diamond segment will affect the cutting depth of each diamond particle. Generally, coarse particles are used for cutting soft materials, while smaller particles are used for cutting tough materials. Therefore, when cutting hard granite, choose diamond with a smaller particle size and higher hardness, and when cutting marble, choosing diamond with a larger particle size and moderate hardness is a better choice.

2: Diamond concentration

The diamond concentration determines the number of diamonds on the cutting surface of the diamond segment. The higher the diamond concentration, the greater the number of diamonds on the surface of the cutting tool, which is beneficial to improve the life. But it is not that the higher the concentration, the better. If the concentration is too high, the surface bonding agent of the segment becomes less, and the structure of the segment becomes weak, which leads to a shorter life. Therefore, to select the appropriate diamond concentration, it is best to find the critical point of the diamond concentration in the segment.

3: Diamond shape

When diamond is under heavy load, the most suitable product is to choose very strong and complete cubic-octahedral diamond. This kind of diamond has the smallest contact surface during the working process and the strongest resistance to breakage, thus reducing equipment power consumption and extending tool life. However, octahedral diamond is not suitable for all. For softer stone, diamond with a weak structure is easier to open, which is convenient for fast cutting.

4: Diamond impurities

Impurities are foreign substances that are wrapped in diamond during growth. The impurities in the diamond not only affect the quality of the diamond during sintering, but also affect the load that the diamond can withstand during cutting. The more diamond impurity in the diamond segment, the more unstable the material will be. On the contrary, the stability of the diamond segment will be higher. Therefore, good diamond segment choose diamonds with less impurities.

5: Impact strength (diamond hardness)

The impact strength is affected by the characteristics of crystal shape, particle size and impurities. When selecting diamond, it is necessary to comprehensively consider the design of the tool, the performance of the bond, the performance of the workpiece material, the power of the machine, the required cutting efficiency and the life, etc. to select the diamond with the appropriate impact strength. The hardness of the diamond in the diamond segment is the core part of the cutting material. The diamond with insufficient strength will be crushed when it is hard and lose the ability to cut. On the contrary, the segment with too hard and not easy to break is easy to be ground. On the contrary, it can not play the role of cutting and grinding stone, which causes the segment to become blunt and increase energy consumption.

Therefore, the selection of diamond in the diamond segment is very particular, and it needs to be determined according to the hardness, wear resistance, and density of the cutting object.

Tags:

The control ratio of the metal content in the diamond segment bond

2020-08-17

The diamond segment is composed of two parts of the bond and the diamond, and the bond is actually not just one component, it is made of paraffin, nickel, tin, zinc, copper, iron, silicon carbide, tungsten and other metal powders, and non-metallic powder, in which copper, iron, silicon carbide and tungsten are the main components, while nickel, tin, and zinc are the metal binders, which make the diamond and the bond more firmly....

Selection of diamond powder for diamond segment

2020-09-24

During the diamond segment working process, the role of diamond powder crystals is very important, especially in the cutting process, a good crystal can be very good in anti-breakage ability, reduce the power consumption of the equipment, and extend the life of the cutting....

Arrayed diamond segment and the saw blade

2020-12-29

In traditional diamond segment products, the diamond powder in the segment is arranged in disorder. During the cutting process, the exposed diamond will impact the stone surface at various angles, and the exposed height of the diamond will vary. As a result, the diamond is not evenly stressed, and diamonds with high exposure are prone to fracture. In order to improve this situation and make the diamond distribution more uniform, arrayed segments have emerged. Weld the arrayed segment on the blade steel body to be an arrayed saw blade....

Commonly used bond for diamond segment

2020-09-09

There are four commonly used bonds for diamond segment. These four bonds are matched with different diamond powders according to different materials to make diamond segments for different purposes. Each bond has its advantages and disadvantages. In the process of designing the diamond segment, we must take advantage and reinforce its shortcomings. This is the charm of diamond segment production and design....

Common problems and treatment methods of diamond segment

2020-08-17

Diamond segment is a non-standard industry in modern industry. The instability of product quality is the most common problem. The following are some of the most prone problems and related solutions in producing diamond segments. Through these instructions, Let everyone better understand the details of diamond segments production process....

Formula design of diamond segment

2020-10-16

Diamond segment is a very special segmented product. Through different formulas and different processes, products with different appearances, different cutting performances and different cutting life can be produced. The most attractive part of this product is that it is not Certainty, especially the new formula, needs to consider factors such as the object to be processed, the matrix metal bond, diamond grade and particle size, pressure and sintering temperature....

RETURN

RETURN