Definition of diamond segment and its components

The cutting element of welding saw blade is commonly known as saw tooth or cutter head. It is a composite sintering body composed of diamond and matrix material. Before being welded into saw blade, the cutting head is called segment. It is made of diamond and bond through mixing, hot pressing sintering, arc grinding and other processes. The shape of the nodal block has sectors and rectangles. In order to adapt to different cutting machines, diamond cutter manufacturers with good service usually have three kinds of diamond cutter heads: fast, medium and slow, and then adjust them according to the performance of specific sawing machines.

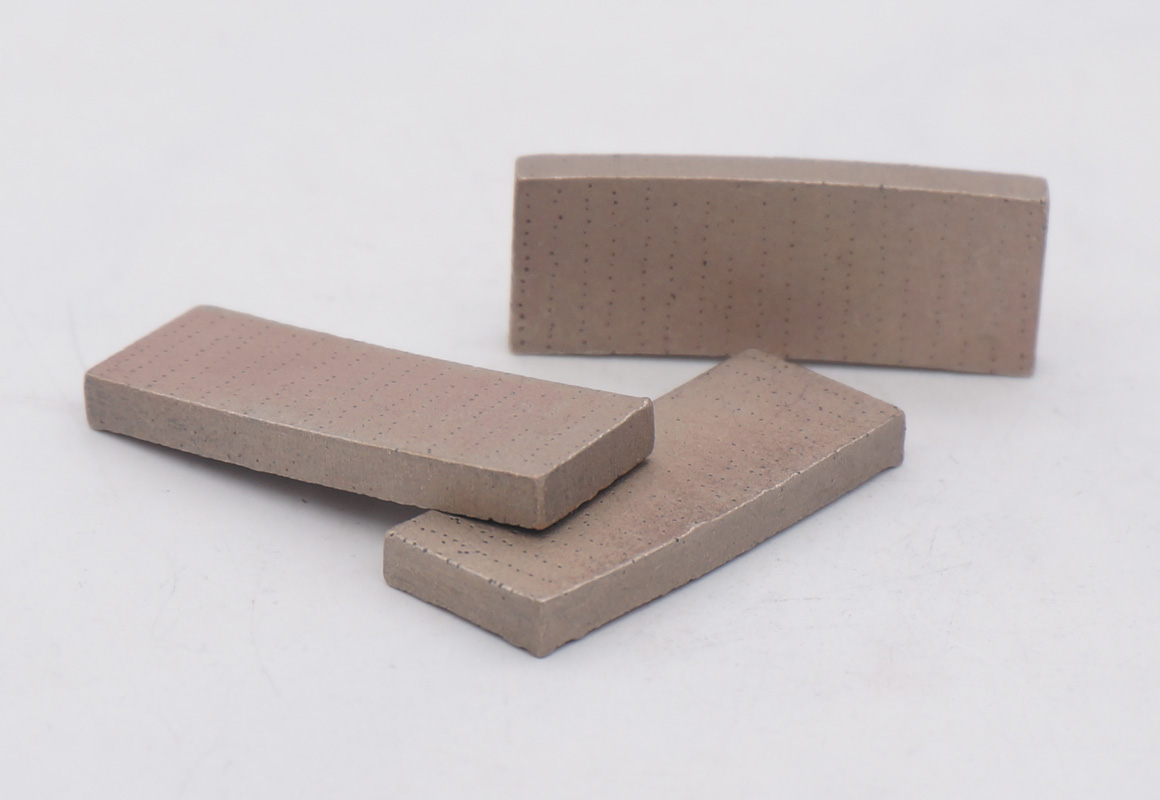

There are various forms of segment, as shown in the figure below, which are usually made into cuboids. The matrix segment should have two basic functions: one is to control the diamond; the other is to wear it with the diamond wear, so that the diamond can be normal out of the edge.

In addition to the hardness and wear resistance, the binder should also have certain toughness. There are four kinds of binders: copper based, cobalt based, iron-based and tungsten carbide based. Among them, cobalt based binder is the best one, but because of its high price, iron-based binder is the most widely used one. There are four added components in the binder: binding component, skeleton component, strengthening component and affinity component. For the binders with different bases, the addition components are also different. In the matrix composition, high melting point metals such as tungsten and tungsten carbide are often used first to adjust the hardness and wear resistance of the matrix. At the same time, copper base alloys such as cobalt, nickel and manganese with low melting point and good chemical affinity to carbon are used as bonding materials for diamond.

The control ratio of the metal content in the diamond segment bond

Selection of diamond powder for diamond segment

Arrayed diamond segment and the saw blade

Commonly used bond for diamond segment

Common problems and treatment methods of diamond segment

RETURN

RETURN