YOU ARE HERE >

HOME >

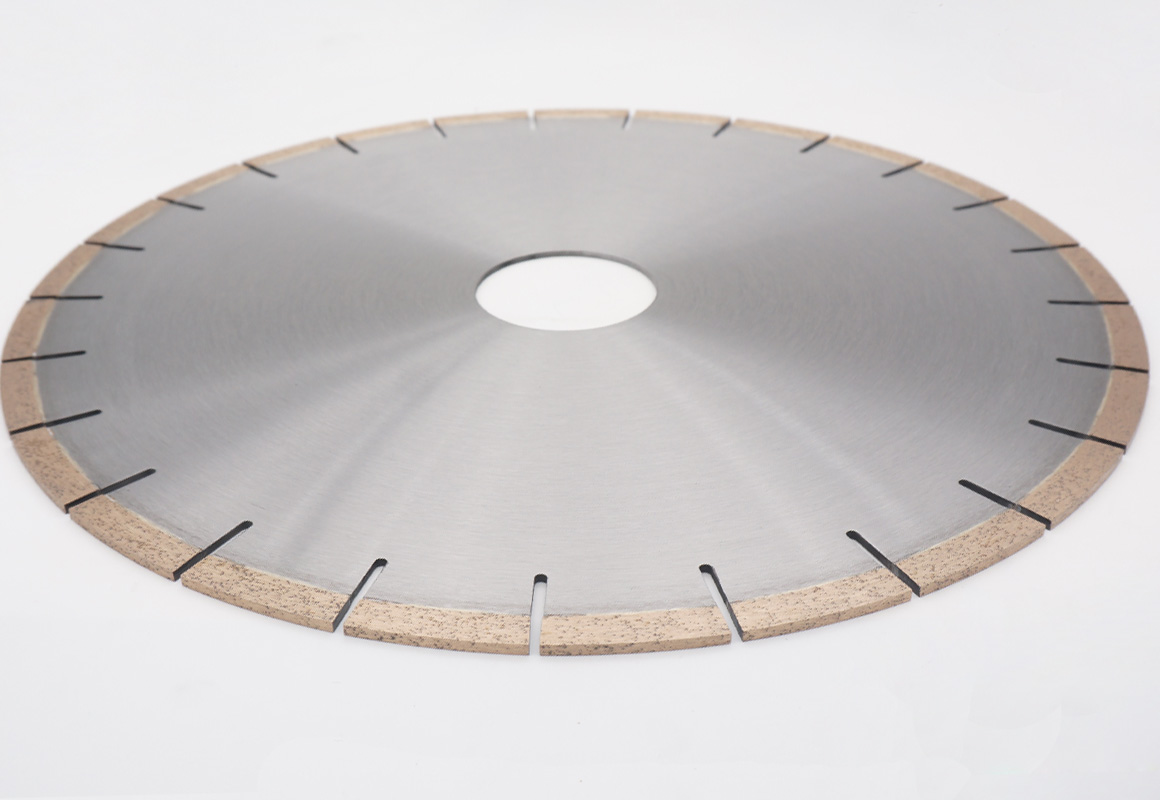

DIAMOND SAW BLADE

Installation and use process of diamond circular saw blade

Publish Date:2020-11-09

The installation and cutting process of diamond circular saw blades is very particular. This article mainly introduces the installation process of different saw blades to let everyone better understand the installation and use of diamond saw blades.1. Installation process:

When installing the saw blade, make sure that the arrow direction marked on the saw blade is exactly the same as the main motor rotation direction of the cutting machine.

¡¾Precautions¡¿

1). When installing the flange, be sure to keep it firmly pressed against the saw blade. After the screw cover is tightened, please confirm that the end jump of the saw blade is at a normal level by hand or with an end jump detector. The operation method: place the dial indicator probe of the end jump detector on the outer edge of the saw blade, and the saw blade is rotated one round. The difference between the highest number and the lowest number displayed on the dial indicator is the end face runout of the saw blade. The smaller the runout, the higher the accuracy. On the contrary, the lower accuracy. Generally speaking, the tighter the flange, the smaller the section runout, and the more stable the cutting.

2). After the saw blade is fixed, Super Cut Tool company will open the saw blade segment, and polish the edge of the blade with a grinding wheel opener and an abrasive belt opener. Generally speaking, through high-speed grinding, let the diamond protrude from the surface of the segment, forming a natural grinding surface.

2. Cutting process:

1). After the diamond saw blade is installed on the cutting machine, need to adjust the cutting gear to the highest level before cutting the stone, and let the saw blade idle for 1-2 minutes; if cutting the thickness is greater than 3 cm, the idle time should be adjusted to 3-4 minutes This function is to ensure that the saw blade has a more stable cutting on the machine, and also allows the saw blade and the machine to have a more suitable bayonet, so as to ensure that the saw blade has a better cutting effect.

2). For medium-diameter saw blades and large-diameter saw blades, the water outlet of the water pipe is aligned with the saw blade and the stone incision. Regarding the water volume should be appropriately adjusted according to the actual cutting situation and the heat condition of the segments to ensure the segment will not overheat. In the process of cutting the stone, remember to ensure that the water flows smoothly, the water pressure is balanced, and the water flow must be sufficient. At least the water flow rate should not be less than 18L/min.

3). Please keep the cutting speed of the saw blade within 60% of the maximum cutting speed in the first 50 meters of the saw blade cutting the stone; after the diamonds are fully exposed, then adjust the saw blade cutting speed to high gear. If the cutting is not moving, you can appropriately reduce the cutting speed and reduce the feeding depth, so that the saw blade segment can better open.

4). Choice of stone machinery, if it is used for cutting slab, usually use constant-speed infrared bridge cutting machines. This kind of sawing speed is 1600-2000r/min. However, if a variable speed bridge cutting machine is used, the selected speed can be 1400r/min-2500r/min, and the speed can be adjusted appropriately according to the cutting situation. The efficiency of the speed adjustment can be appropriately adjusted according to the following table.

| Medium hardness to soft, high density of quartz, fine grains | Medium hardness to hard, large quartz grains | Medium hardness to soft, easy to fragile large | Slab trimming, cutting depth over 35mm | |

| Net backed | 7£8 m/min | 8£9m/min | 6£6.5m/min | 5£6m/min |

| No net backed | 5£7 m/min | 6£8m/min | 5£6m/min |

5). When cutting fragile stone such as Lightning Beige, Yunnan Beige, Golden Carrara White, etc., the cutting speed of the saw blade should be appropriately reduced to prevent the stone from cracking. If you encounter hard and difficult-to-cut stone types, such as stone island red, electrolytic plate, quartz stone, night rose, etc., at this time, reduce the cutting speed appropriately, and you need to hold the stone and use heavy objects to further fix the stone slab. Of course, it is extremely necessary to choose a sharper saw blade.

During the cutting process, maintaining stable cutting is the most important thing. If there is a cutting problem, whether it is mechanical or saw blade reasons, it should be solved in time.

Tags:

.jpg)

Installation and use process of diamond circular saw blade

2020-11-09

Diamond saw blades can be used in single blade saw, multiblade saws, infrared bridge cutting machines, hand cutter and other large and medium-sized stone machinery according to their sizes. They can also be used in angle grinders, hand cutting machines etc., the small machines are used in a wide range. This article is mainly based on the application of different saw blades in installation and cutting....

.jpg)

Diamond circular saw blade classification

2020-11-09

Diamond circular saw blades are mainly classified according to size. Generally speaking, they are divided into small-diameter saw blades, medium-diameter saw blades and large saw blades. Small saw blades are also divided according to the shape of the blade, while medium-diameter saw blades can be divided according to the cutting material or the shape of the segment, and the large saw blade is divided according to the purpose. This article introduces the classification of circular saw blades to let you better understand the relevant knowledge of diamond saw blades....

The development of diamond saw blades

2020-09-24

Among all diamond tools, diamond saw blades are the first to appear. With saw blades, cutting becomes simple. Cutting changes the entire world. In terms of decorative materials, wood is not the only choice. Stone, artificial stone, and ceramic tiles are used extensively. In terms of engineering, the cutting of asphalt, reinforced concrete and other materials has also become simpler....

Five common diamond circular saw blades

2020-12-31

Diamond circular saw blades are the largest sales volume of diamond products, accounting for more than 95% of the total sales of diamond tools. In recent years, China has conducted a lot of research on optimizing the formula of diamond circular saw blades, which has made the sawing function of diamond circular saw blades significantly improved, and the cost of blades has been greatly reduced, making domestic saw blades have strong competitiveness at home and abroad. At present, there are mainly five common circular saw blades on the market. This article gives a detailed introduction to these five different saw blades....

Common process of diamond circular saw blade

2020-09-09

Diamond circular saw blades have different manufacturing methods, and different manufacturing methods allow the saw blade to have different performances after being manufactured. And different processes can make saw blades have different sawing processes. This article introduces four common methods of circular saw blades to let everyone know about the production process of circular saw blades....

Diamond saw blade production process

2020-11-09

Diamond saw blade is a product of the combination of diamond segment and alloy blade body. This article describes the entire saw blade production process from segment production, blade body procurement, saw blade welding, inspection and testing, storage and packaging....

RETURN

RETURN