YOU ARE HERE >

HOME >

DIAMOND SAW BLADE

How to identify the sharpness of diamond circular saw blades

Publish Date:2020-08-17

There are many types of diamond saw blades, different sizes and blank blade quality, and various cutting slot accuracy, so it seems that there is no way to identify the sharpness. In fact, the sharpness of two saw blades with same size and almost the same appearance are different sharpness performance, and identification is necessary.Traditional Chinese medicine pays attention to look, listen, ask and feel the pulse. In fact, the process of selecting saw blades is also the same, but without the smell process, we will introduce from the other three aspects:

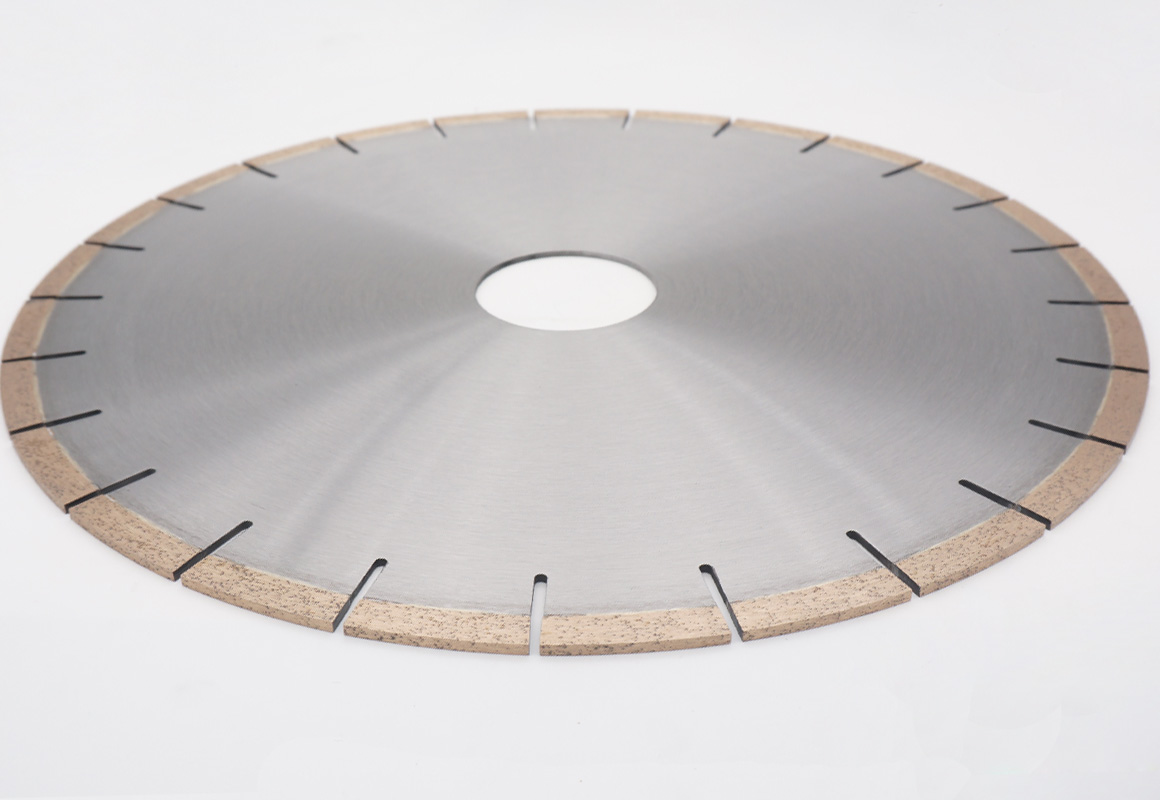

look: It means to look at it. It doesn’t mean looking at it casually or just looking at it. The first thing to look at is the segment. The saw blade segment is the most important part of the entire cutting process. Look at these three aspects. :

The first one is the distribution of diamonds in the segment. If the diamonds powders distribute more and densely at the top of segment, the cutting effect of such a saw blade is generally not too bad. If you see that the distribution is very loose, then the saw blades become very blunt due to the lack of cutting material.

The second one is the exposure effect of the diamond powder on the segment. After the blade is opened, we will find that the diamond is distributed on the surface of the segment. The exposure effect of a good diamond blade is very obvious, you can see that the diamonds are protruding and embedded in the surface of the segment, in this case the blade sharpness is very good. If the diamond still cannot protrude on the surface of the segment after the blade is opened, then you can realize the sharpness of the segment will be not good.

Third, we can look at the junction of the diamond segment and the blank blade body, where the segment is welded. If the segment is straight, we can see that blank blade body is directly embedded in the segment bond. Such segment is well welded. On the contrary, abrasion, improper segment, severe oxidation, blackening of the weld, etc. are abnormal. If the diamond segment is welded well, the stability is better when cutting. If the segment is not well welded, then the segment will fall out, which will affect the sharpness.

After look, we have to ask about it, and we must ask the seller clearly how many meters the saw blade can cut, whether it is a sharp type or a long-life type, it suitable for cutting which hardness stone, and is it good for universal cutting or not. After asking these questions, you are basically ready for the subsequent after-sales and rights protection.

The last step is to feel the pulse. We may not feel the sharpness of the saw blade by hand, but we can touch whether the welding joint has been processed or not, whether the blade body is flat or not, touch the spray paint on the saw blade is rough or not, and touch the thickness of the blade body, you can also pull it hard to check the toughness of the blade body. These methods are to check the workmanship of the product. Generally, the sharpness of the well-made saw blade is acceptable. If the workmanship is not good, then you can only resign to have good sharpness.

Tags:

.jpg)

Installation and use process of diamond circular saw blade

2020-11-09

Diamond saw blades can be used in single blade saw, multiblade saws, infrared bridge cutting machines, hand cutter and other large and medium-sized stone machinery according to their sizes. They can also be used in angle grinders, hand cutting machines etc., the small machines are used in a wide range. This article is mainly based on the application of different saw blades in installation and cutting....

.jpg)

Diamond circular saw blade classification

2020-11-09

Diamond circular saw blades are mainly classified according to size. Generally speaking, they are divided into small-diameter saw blades, medium-diameter saw blades and large saw blades. Small saw blades are also divided according to the shape of the blade, while medium-diameter saw blades can be divided according to the cutting material or the shape of the segment, and the large saw blade is divided according to the purpose. This article introduces the classification of circular saw blades to let you better understand the relevant knowledge of diamond saw blades....

The development of diamond saw blades

2020-09-24

Among all diamond tools, diamond saw blades are the first to appear. With saw blades, cutting becomes simple. Cutting changes the entire world. In terms of decorative materials, wood is not the only choice. Stone, artificial stone, and ceramic tiles are used extensively. In terms of engineering, the cutting of asphalt, reinforced concrete and other materials has also become simpler....

Five common diamond circular saw blades

2020-12-31

Diamond circular saw blades are the largest sales volume of diamond products, accounting for more than 95% of the total sales of diamond tools. In recent years, China has conducted a lot of research on optimizing the formula of diamond circular saw blades, which has made the sawing function of diamond circular saw blades significantly improved, and the cost of blades has been greatly reduced, making domestic saw blades have strong competitiveness at home and abroad. At present, there are mainly five common circular saw blades on the market. This article gives a detailed introduction to these five different saw blades....

Common process of diamond circular saw blade

2020-09-09

Diamond circular saw blades have different manufacturing methods, and different manufacturing methods allow the saw blade to have different performances after being manufactured. And different processes can make saw blades have different sawing processes. This article introduces four common methods of circular saw blades to let everyone know about the production process of circular saw blades....

Diamond saw blade production process

2020-11-09

Diamond saw blade is a product of the combination of diamond segment and alloy blade body. This article describes the entire saw blade production process from segment production, blade body procurement, saw blade welding, inspection and testing, storage and packaging....

RETURN

RETURN