YOU ARE HERE >

HOME >

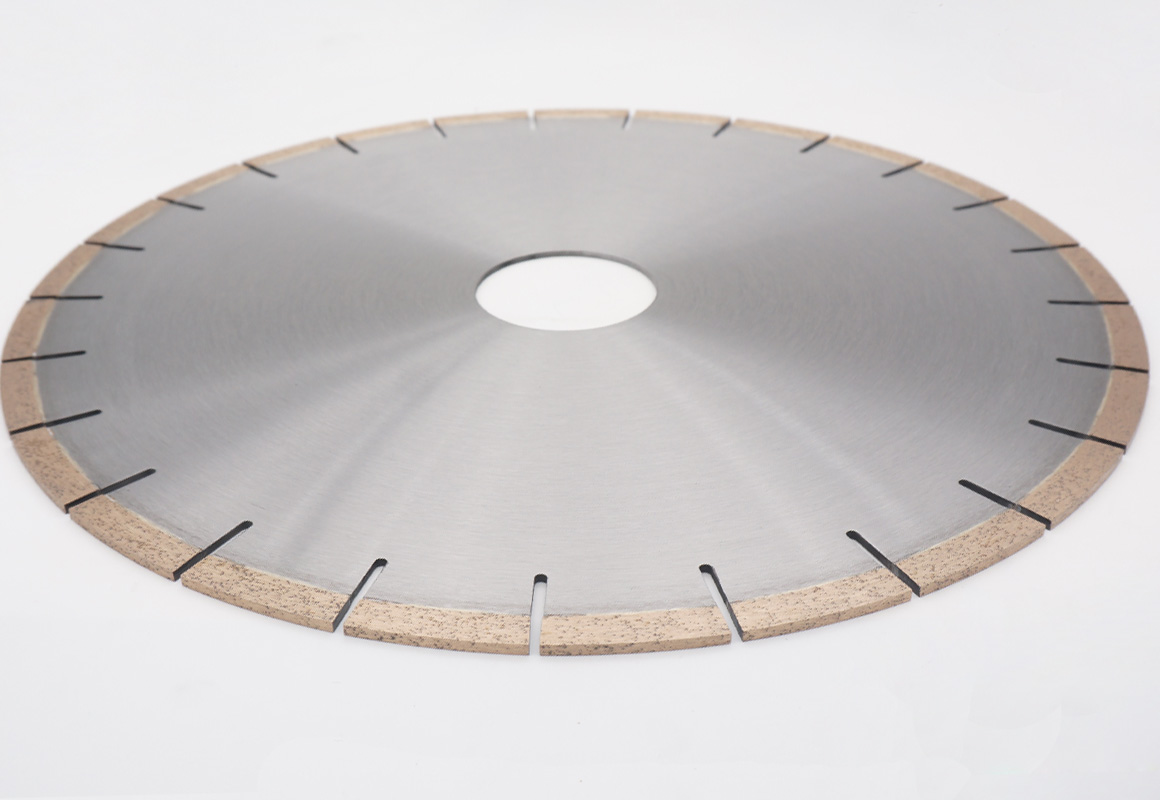

DIAMOND SAW BLADE

Diamond saw blade production process

Publish Date:2020-11-09

Super Cutting Diamond Tool company has 17 years of experience in diamond segment processing. Since 2018, the company has introduced saw blade processing machinery such as cold press sintering machines and automatic welding machines. Since then, Super Cut Tool company has been able to process all kinds of large, medium and small diamond saw blade products. Below, we will explain from various aspects such as segment production, blade body procurement, saw blade welding, inspection and testing, storage and packaging.

1. Segment production

1). Ingredients: The production technicians of the Super Cutting Diamond Tool company will adjust the product formula suitable for the customer according to the customer's needs, which are diamond powder, metal powder, bonding agent and other materials, and weigh them according to the appropriate ratio.

2). Mixing: The weighed materials are fully stirred and mixed by the fully automatic 3D blender, so that the material powder is completely mixed. Generally speaking, the materials after mixing are evenly distributed to ensure the stability of the quality of the segment.

3). Cold pressing: Our company adopts fully automatic CNC cold press, high-precision steel molds, and presses the agglomeration of the segment through high pressure to ensure the precise size of the cold-pressed segment and ensure the excellent cutting effect. At the same time that the cold pressing tool head is agglomerated, the non-working layer must be processed.

4). Hot pressing: Super Cut Tool company is equipped with 30 automatic sintering machine. The high-quality sintering machine ensures that the segment has accurate temperature and pressure during the sintering process. In the process of heating and pressurizing, the metal powder of the segment undergoes physical and chemical changes, especially the metal powder, the bonding agent, through high temperature, the metal melts and combines to form a harder metal block. After the segment is cooled, the metal block tightly and powerfully wraps the diamond particles, so that the segment has better cutting performance and holding power.

5). Cooling and grinding: After cooling, take out the diamond segment from graphite mold, start to polish the corners and surface to remove burrs, and make the segment look smooth and beautiful.

2. blade body selection process

At present, most saw blade manufacturers in China choose domestic blade body, mainly high-speed steel, alloy steel and other steel materials. Among them, anti-rust treatment, the rigidity, elasticity, weight, size, etc. are required to test to select a better blade body material.

Saw blade welding, opening and packaging

1). Welding: At present, Super Cut Tool company uses two welding machines, high-frequency welding and laser welding to weld the segment. Generally speaking, high-frequency welding is more efficient, and welding is carried out by welding glue and solder. This welding method is widely use because it is cheap. However, laser welding uses local heating and combines the base body and the segment itself. This welding method has extremely high firmness, and there will be no loss of the segment in the later period, thereby increasing the use efficiency and life of the segment. Laser welding saw blades are prone to deform the blade body, so this welding method is generally not used for large diameter saw blades.

2). Opening: At present, Super Cut Tool company has more than 20 units opening grinders and 5 units belt grinding machines, which can quickly complete segment opening. After the opening, the diamond powder of the segment is completely exposed on the surface. It can be used directly for cutting.

3). Packaging: Super Cut Tool company will perform anti-rust treatment on the medium-diameter saw blade, including electroplating solution, anti-rust paint, packaging, using plastic bag as inner packaging, outer packaging as carton packaging, and finally in a group of multiple pieces of wood box packaging can also be packaged according to customer requirements.

Testing and inspection

Super Cut Tool company adopts strict raw material testing, and conducts quality control tests through single crystal three-dimensional structure, purity, strength, and purity of metal powder. In the manufacturing process of the segment, each price process of the segment is weighed, size measurement, hardness test, wear resistance test, etc., through the test, the product quality is more stable. Finally, the saw blade must be tested and inspected for welding strength and impact resistance.

Tags:

.jpg)

Installation and use process of diamond circular saw blade

2020-11-09

Diamond saw blades can be used in single blade saw, multiblade saws, infrared bridge cutting machines, hand cutter and other large and medium-sized stone machinery according to their sizes. They can also be used in angle grinders, hand cutting machines etc., the small machines are used in a wide range. This article is mainly based on the application of different saw blades in installation and cutting....

.jpg)

Diamond circular saw blade classification

2020-11-09

Diamond circular saw blades are mainly classified according to size. Generally speaking, they are divided into small-diameter saw blades, medium-diameter saw blades and large saw blades. Small saw blades are also divided according to the shape of the blade, while medium-diameter saw blades can be divided according to the cutting material or the shape of the segment, and the large saw blade is divided according to the purpose. This article introduces the classification of circular saw blades to let you better understand the relevant knowledge of diamond saw blades....

The development of diamond saw blades

2020-09-24

Among all diamond tools, diamond saw blades are the first to appear. With saw blades, cutting becomes simple. Cutting changes the entire world. In terms of decorative materials, wood is not the only choice. Stone, artificial stone, and ceramic tiles are used extensively. In terms of engineering, the cutting of asphalt, reinforced concrete and other materials has also become simpler....

Five common diamond circular saw blades

2020-12-31

Diamond circular saw blades are the largest sales volume of diamond products, accounting for more than 95% of the total sales of diamond tools. In recent years, China has conducted a lot of research on optimizing the formula of diamond circular saw blades, which has made the sawing function of diamond circular saw blades significantly improved, and the cost of blades has been greatly reduced, making domestic saw blades have strong competitiveness at home and abroad. At present, there are mainly five common circular saw blades on the market. This article gives a detailed introduction to these five different saw blades....

Common process of diamond circular saw blade

2020-09-09

Diamond circular saw blades have different manufacturing methods, and different manufacturing methods allow the saw blade to have different performances after being manufactured. And different processes can make saw blades have different sawing processes. This article introduces four common methods of circular saw blades to let everyone know about the production process of circular saw blades....

Diamond saw blade production process

2020-11-09

Diamond saw blade is a product of the combination of diamond segment and alloy blade body. This article describes the entire saw blade production process from segment production, blade body procurement, saw blade welding, inspection and testing, storage and packaging....

RETURN

RETURN