YOU ARE HERE >

HOME >

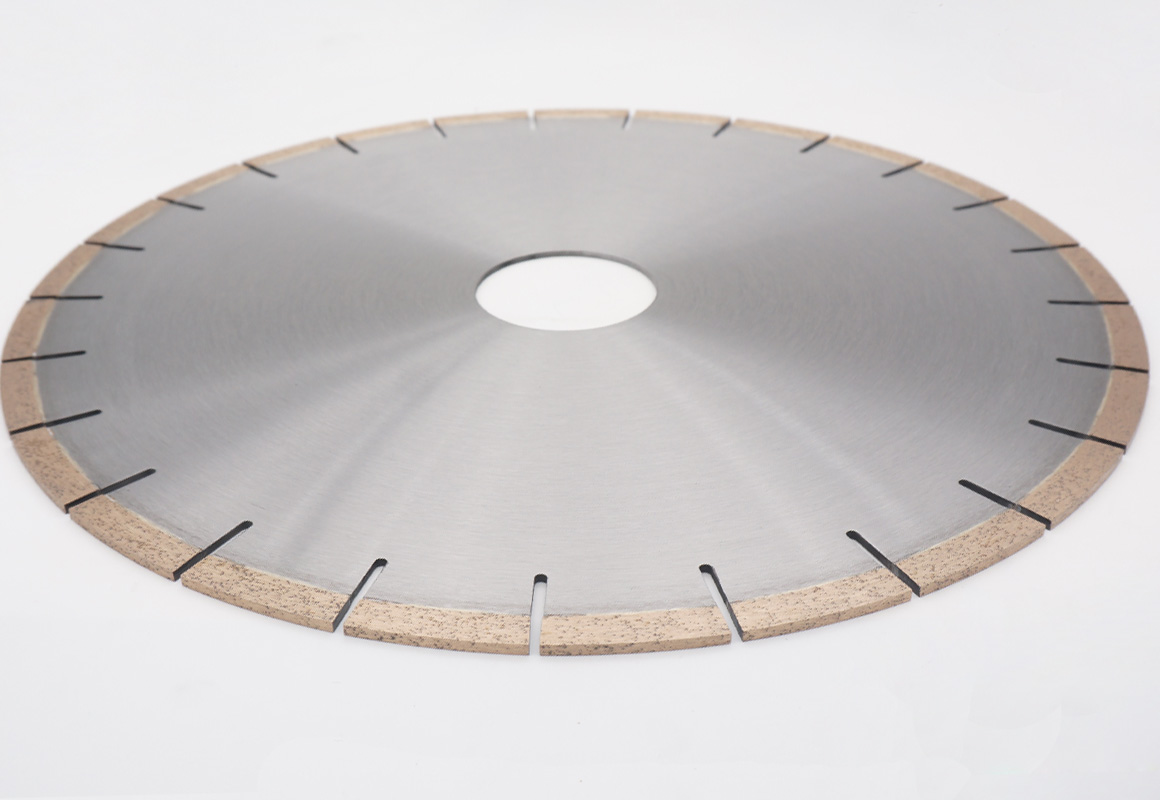

DIAMOND SAW BLADE

Common process of diamond circular saw blade

Publish Date:2020-09-09

There are many types of diamond circular saw blades, which have different uses in different occasions, and their manufacturing methods are also different. This chapter focuses on the production and processing techniques of various saw blades, as well as the basic of the production processes, principle and product features contained in these techniques. This article introduces several commonly used circular saw blade production methods:(1) Electroplating method: A variety of diamond tools can be manufactured using electroplating method. The electroplating method is carried out under normal temperature and pressure. It does not damage the diamond and is easy to operate. It is especially suitable for manufacturing special-shaped diamond tools, such as diamond dressing wheels, internal circular cutting blades, external circular saw blades, wire saw steel sections, and belts saws and wire saws, etc. The cutting disc manufactured by electroplating has good adhesion to the blade steel body, strong holding power to diamond, and can be made very thin, high cutting efficiency, strong wear resistance, and significant economic benefits.

(2) Rolling method: The steel body of the rolling saw blade is a softer low-carbon steel, and a very narrow slot is formed on the periphery of the outer circle. The diamond is coated on the outer circle, then, a steel extrusion wheel is used to squeeze the diamond into the seam and plastically deform the steel body material to firmly embed the diamond. Rolling saw blades are only used for cutting watch gems and processing rare earth ferrites.

(3) Sintering method: The powder sintering method has been the most widely used in the manufacture of diamond saw blades. From traditional cold pressing and sintering saw blades to excellent performance hot pressing and multiple welding saw blades, powder sintering method of manufacturing can be used.

(4) Vacuum brazing method: Vacuum brazing is a relatively method, which is characterized in that there are open long grooves evenly distributed along the circumference of the saw blade body, and the diamond particles with metal composite coating are directly filled by the brazing method. Equipped with long open slots on the circumference of the saw blade base body. The brazing process is currently limited by technology and can only be welded with a single layer of diamond, so the welding area is small, resulting in a short life and large waste of the steel body.

.jpg)

Tags:

.jpg)

Installation and use process of diamond circular saw blade

2020-11-09

Diamond saw blades can be used in single blade saw, multiblade saws, infrared bridge cutting machines, hand cutter and other large and medium-sized stone machinery according to their sizes. They can also be used in angle grinders, hand cutting machines etc., the small machines are used in a wide range. This article is mainly based on the application of different saw blades in installation and cutting....

.jpg)

Diamond circular saw blade classification

2020-11-09

Diamond circular saw blades are mainly classified according to size. Generally speaking, they are divided into small-diameter saw blades, medium-diameter saw blades and large saw blades. Small saw blades are also divided according to the shape of the blade, while medium-diameter saw blades can be divided according to the cutting material or the shape of the segment, and the large saw blade is divided according to the purpose. This article introduces the classification of circular saw blades to let you better understand the relevant knowledge of diamond saw blades....

The development of diamond saw blades

2020-09-24

Among all diamond tools, diamond saw blades are the first to appear. With saw blades, cutting becomes simple. Cutting changes the entire world. In terms of decorative materials, wood is not the only choice. Stone, artificial stone, and ceramic tiles are used extensively. In terms of engineering, the cutting of asphalt, reinforced concrete and other materials has also become simpler....

Five common diamond circular saw blades

2020-12-31

Diamond circular saw blades are the largest sales volume of diamond products, accounting for more than 95% of the total sales of diamond tools. In recent years, China has conducted a lot of research on optimizing the formula of diamond circular saw blades, which has made the sawing function of diamond circular saw blades significantly improved, and the cost of blades has been greatly reduced, making domestic saw blades have strong competitiveness at home and abroad. At present, there are mainly five common circular saw blades on the market. This article gives a detailed introduction to these five different saw blades....

Common process of diamond circular saw blade

2020-09-09

Diamond circular saw blades have different manufacturing methods, and different manufacturing methods allow the saw blade to have different performances after being manufactured. And different processes can make saw blades have different sawing processes. This article introduces four common methods of circular saw blades to let everyone know about the production process of circular saw blades....

Diamond saw blade production process

2020-11-09

Diamond saw blade is a product of the combination of diamond segment and alloy blade body. This article describes the entire saw blade production process from segment production, blade body procurement, saw blade welding, inspection and testing, storage and packaging....

RETURN

RETURN