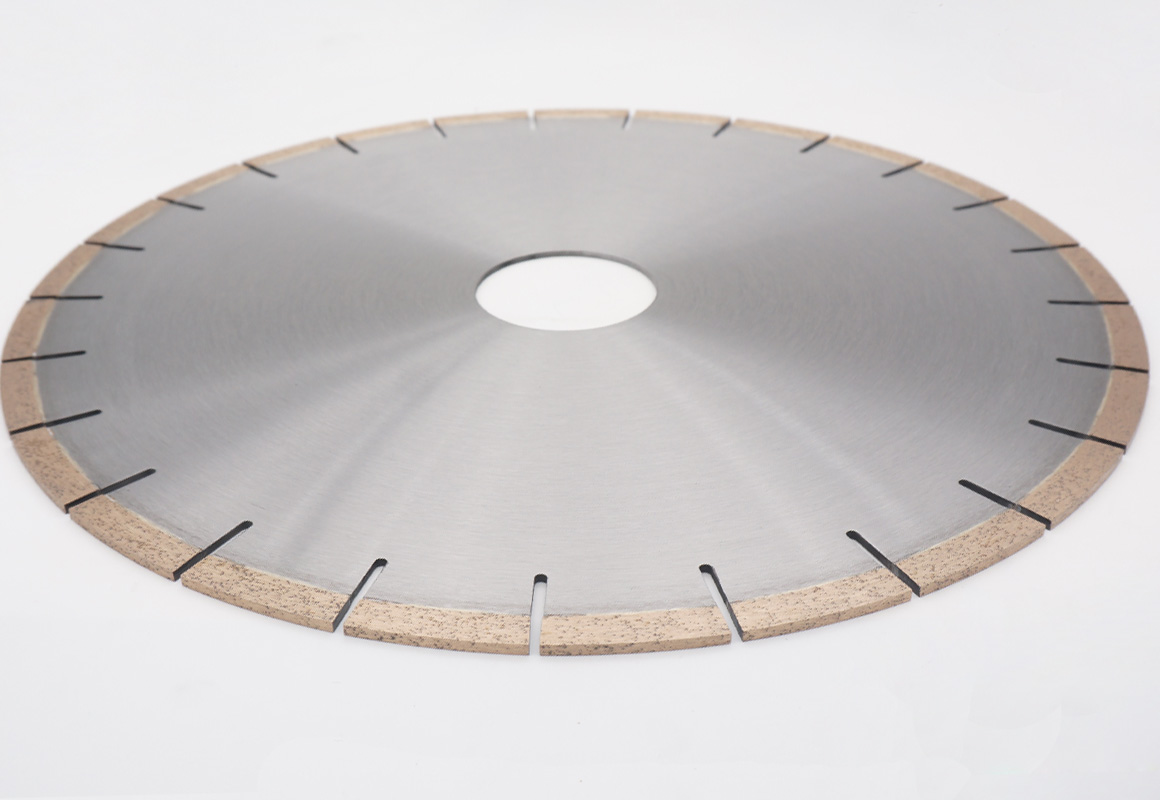

Classification of small and medium-sized stone impregnated saw blades

Improved and improved to make it safe to use. Since the development of the saw blade for dry cutting, it has some advantages in operation and use. Such as higher circumferential cutting speed and cutting efficiency without reducing the service life, solid dry cutting replaces traditional resin cutting in favor of cooling wet cutting diamond saw blades. What's more important is that the dry cutting process keeps it cool in water. Providing difficult areas makes it easier to use, while saving costs by reducing subsequent removals.

For the cutting of difficult-to-cut materials, this particular market product is generally divided into three different categories based on the performance of the saw blade. The category is "specialized saw blade". This type of saw blade is mainly used by professional building contractors. Power semi-automatic cutting machine. In order to meet the requirements of high cutting speed, reliable and durable, balanced operation, long service life, and low downtime, 30-50 US purpose high-strength diamond and abrasion-resistant bonding agent are set and sintered.

The second type of saw blade is a "semi-dedicated blade" (also known as a universal blade), which is mainly used by distributors and building contractors for discontinuous long-term use. This type of blade is generally required to Different materials have constant cutting efficiency. This type of saw blade generally uses 40/50 mesh medium strength diamond.

The third type of saw blade is the "diy" type. Sharp diamonds and softer bonding agents that are inexpensive and have good brittleness can be used.

These are the common manifestations of the style and structure of commonly used small and medium-sized saw blades.

.jpg)

Installation and use process of diamond circular saw blade

.jpg)

Diamond circular saw blade classification

The development of diamond saw blades

Five common diamond circular saw blades

Common process of diamond circular saw blade

RETURN

RETURN