Introduction of diamond fickert

Publish Date:2020-10-16

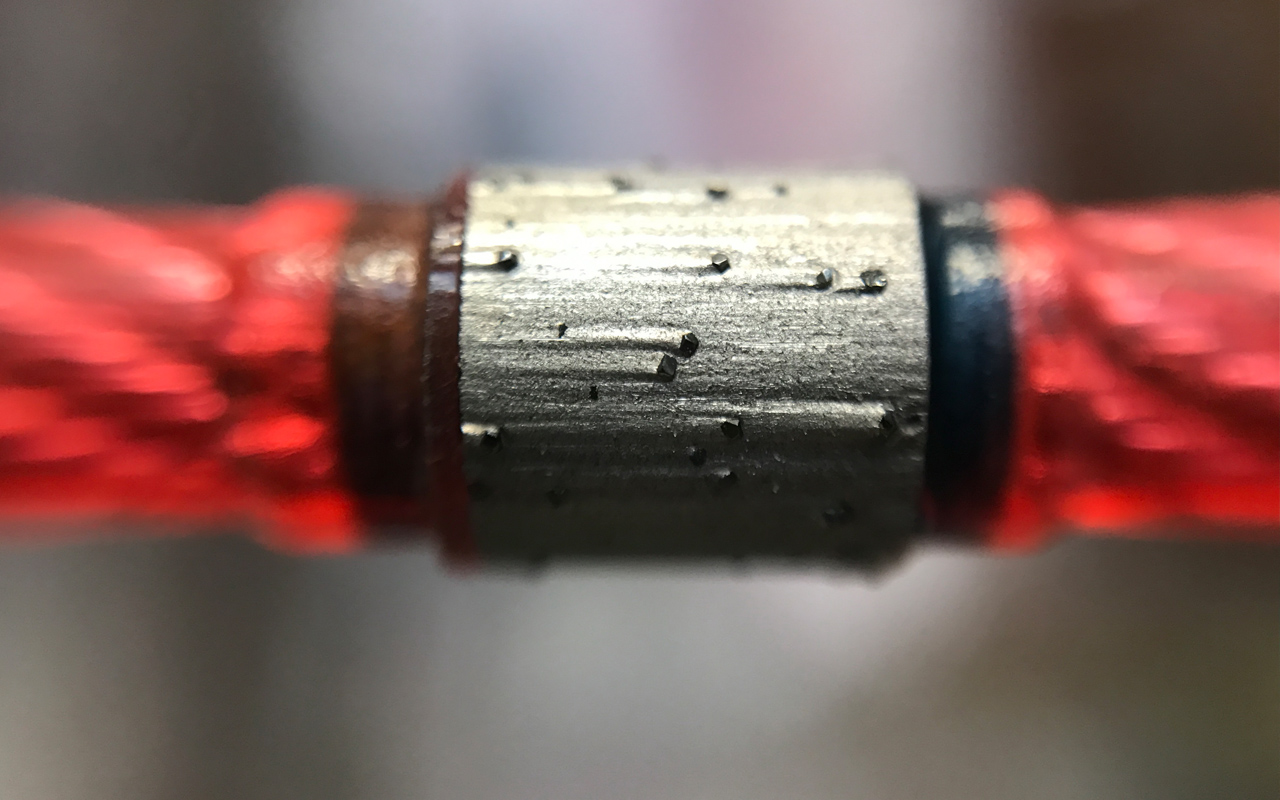

Diamond fickert is suitable for single-head or multi-head granite polishing line machine. It is mainly used for multi-head grinders, especially the large slab polishing machine, which must be equipped with the diamond fickert.The diamond segment of the diamond fickert use coarse diamond particles and with variety of metals or metal compound powders as the bond, s sintered at high temperature and pressure, the composition is reasonable, and the abrasive particles are firmly bonded to the bond during use. It is not easy to fall off and has a long service life. It can be used to process various hard materials, such as, granite, terrazzo, etc., and can improve its processing accuracy, especially for the production of automatic granite polishing lines, with good sharpness, strong cutting force, good wear resistance and high cost performance.

The use of diamond fickert has the following advantages:

1. Power saving: diamond grinding block can grind stone with smaller force due to its super sharpness. Because the pressure of the grinding head can be greatly reduced, the wear of the machine reduce, and the processing of the same thickness slab can reduce the stone slab damage rate, and it can also process the thinner stone slab;

2. High efficiency: Diamond grinding block can stably increase the speed of the conveyor belt due to its super sharpness and wear resistance, thereby improving production efficiency;

3. High gloss: diamond grinding blocks can increase the stone gloss by more than 10 degrees. Due to the advanced production process, the diamond abrasive block can completely avoid the reduction of magnesium oxide activity during the production process and the change of curing conditions, which makes the quality of the abrasive block unstable; the diamond production and testing process and transportation process are more strict than carbonized Silicon, and the uniformity of diamond particle size is much greater than that of silicon carbide, so the possibility of causing stone scratches and gloss instability is greatly reduced;

4. Reliable quality: Due to the large-scale production of diamond, the price has been greatly reduced, so the price of diamond grinding blocks has also been greatly reduced. In addition, the production of diamond grinding blocks can use computer-controlled production equipment and processes, The production of magnesite blocks still uses simple manual production equipment and processes, the production cycle is more than one month, which affects the quality for a long time, and the quality cannot be stable.

Generally speaking, the life of a set of diamond fickert (6 pcs per set) used for rough grinding is between 12,000 and 15,000sqm, and for fine grinding is between 35,000 and 50,000sqm. Such a long life allows the diamond fickert to extend the maintenance and the time. In terms of stability, the diamond fickerts are also better than grinding discs.

Tags:

Polishing technology and principle of natural stone

2020-08-17

Natural stone needs to face the most basic technological processes such as cutting, grinding and polishing during the processing. Polishing is an important step in stone processing. We need to understand the polishing process and principles of stone processing, so as to facilitate us to master stone processing Basic knowledge also gives us a better understanding of the stone industry....

Diamond fickert length and style

2020-12-31

The shape of the diamond fickert has already been determined in terms of styling. The main difference lies in the change of its length and the style. Generally speaking, the commonly used lengths of the diamond fickert are 130mm, 135mm, 145mm, 170mm. On the one hand, abrasive agglomeration can be divided into two types: slotted and continuous. This article mainly introduces the influence of diamond fickert different lengths and different styles of on stone processing....

Granite Polishing Products-Metal bond diamond fickert afickertsive

2020-12-31

Diamond fickert is a product used in the automatic granite polishing line. It is mainly used in fickert-type polishing machine. The biggest feature of this machine is that there are 6-7 firkets installation grooves on the bottom of the polishing head. It is used for rough grinding of granite slabs, so it is placed at the front of the granite polishing line, and the front is connected with the califickertting afickertsives....

Resin bond diamond fickert

2020-12-31

Diamond is the main tool for grinding stone. After rough grinding the granite slab with metal bond diamond fickert, it is necessary to further process the stone that has completed the rough grinding process. At this time, the resin bond diamond fickert which made by diamond and resin bonded came into being. This kind of product performs finer grinding on the surface of granite slabs, also known as fine grinding. After fine grinding, the surface of the slab is basically flat and presents a matt surface....

Introduction of diamond fickert

2020-10-16

Diamond fickert is a common abrasive used in stone polishing machinery. It is mainly composed of diamond segment and steel base. The steel base part is used to be fixed on the grinding head of the polishing machine. A grinding head can be inlaid with 6-7 pieces diamond fickert. During the operation, the diamond fickert polishes the slabs in all directions through the rotation of the grinding head on the polishing machine and the forward and backward movement of the grinding machine crossbeam....

Diamond fickert production process

2020-12-31

Diamond fickert is composed of steel base and fickert abrasive block. In the process of producing diamond fickert, the steel base is basically purchased from alloy steel supplier. The steel body material requires high temperature resistance and must can be formed into a compact one-piece structure with the fickert abrasive block, and the other part is the fickert abrasive block, which is also the focus of this article....

RETURN

RETURN